In the realm of fluid control systems, Teflon check valves have emerged as essential components, renowned for their durability and chemical resistance. According to Dr. Emily Carter, a leading expert in valve technology, "Choosing the right Teflon check valve is crucial for ensuring optimal performance and longevity in a system." This statement underscores the importance of selecting high-quality valves to prevent backflow and maintain system efficiency.

Teflon check valves, specifically made from polytetrafluoroethylene (PTFE), offer unparalleled resistance to corrosion and wear, making them ideal for demanding environments. Industries such as chemical processing, pharmaceuticals, and food and beverage rely heavily on these valves to manage flow effectively while preventing contamination. Understanding the variations in design and function among the top Teflon check valves can greatly impact the operational reliability of your systems.

As we delve into the top five Teflon check valves available on the market, it’s essential to consider factors such as flow rate, pressure rating, and installation ease. This guide will provide valuable insights that empower you to make informed decisions, ensuring that your applications run smoothly and efficiently while maximizing the performance of Teflon check valves.

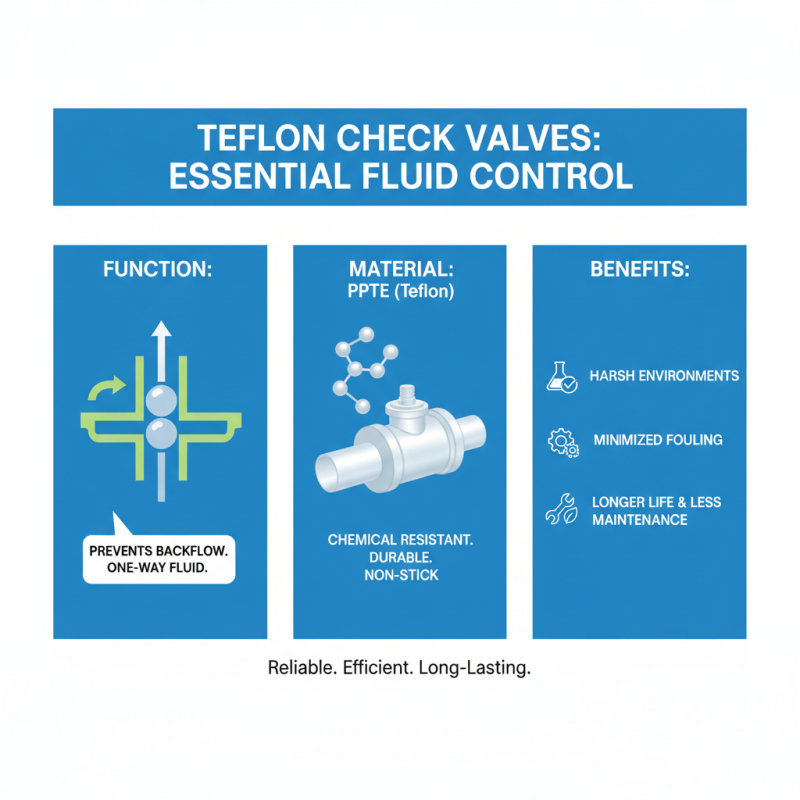

Teflon check valves are essential components in various industries, known for their ability to prevent backflow while allowing fluid to pass in one direction. Made from polytetrafluoroethylene (PTFE), these valves are particularly valued for their chemical resistance and durability, making them ideal for use in harsh environments. The non-stick nature of Teflon also helps to minimize fouling, ensuring a longer operational life and less maintenance compared to traditional materials.

These valves find applications across various sectors, including pharmaceuticals, food processing, and chemical manufacturing. They are commonly used in systems where the integrity of the flow is critical, such as in pumps and piping systems that handle aggressive chemicals or sterile products. By ensuring one-way flow and preventing contamination, Teflon check valves contribute significantly to the efficiency and safety of industrial processes. When selecting the right Teflon check valve for a specific application, it is important to consider factors such as pressure ratings, temperature limits, and the nature of the fluids being handled to achieve optimal performance.

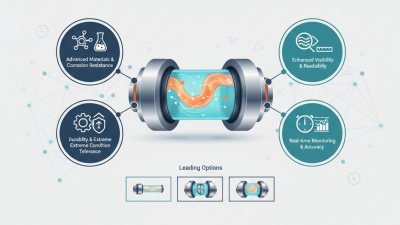

When selecting Teflon check valves, there are several key features to keep in mind to ensure optimal performance.

First, consider the valve design and its suitability for your specific application.

Teflon check valves are available in various designs, including spring-loaded and ball-type checks.

Each design offers distinct benefits depending on factors such as the required flow rate, backpressure conditions, and the type of fluid being handled.

Understanding these nuances will help you choose a valve that can handle the demands of your system.

Another important aspect is the temperature and pressure ratings of the valve.

Teflon is known for its excellent chemical resistance and high-temperature tolerance; however, it is crucial to match the valve's specifications with the application's requirements.

Pay close attention to the maximum working pressure, as this can significantly affect the valve’s longevity and reliability.

Additionally, assess the compatibility of the Teflon material with the fluids to avoid potential degradation over time.

Finally, evaluate the ease of installation and maintenance.

A valve that is easy to install and service can minimize downtime and enhance overall efficiency in your operations.

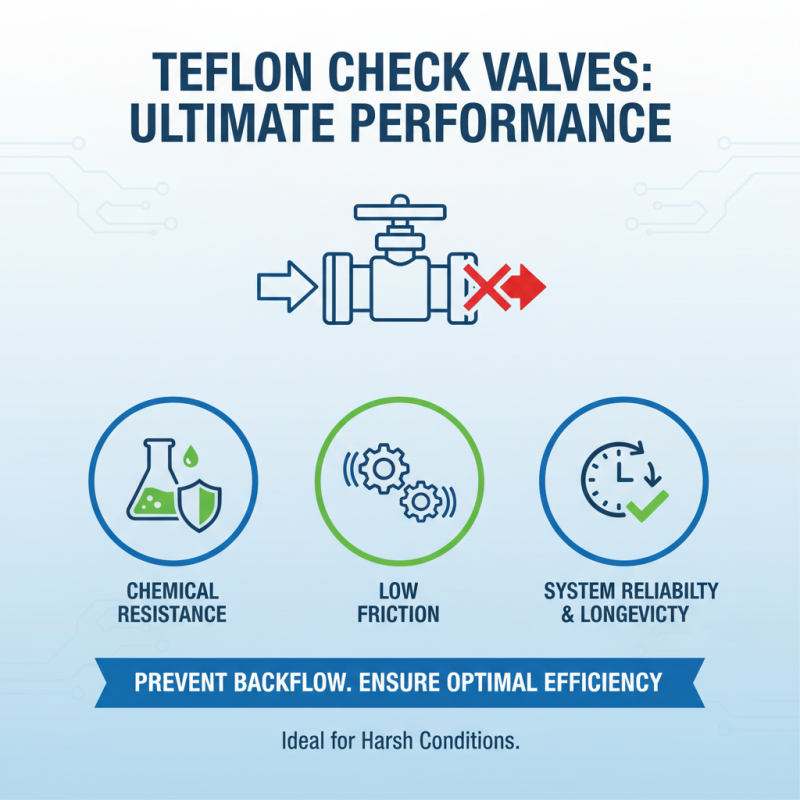

When it comes to choosing Teflon check valves, performance is paramount. These valves are designed to prevent backflow in various systems, ensuring optimal efficiency and functionality. Teflon, known for its exceptional chemical resistance and low friction properties, is an ideal material for valves that are exposed to harsh conditions. Selecting the right Teflon check valve can significantly impact the reliability and longevity of your system.

Among the top recommended options are valves that feature robust designs and high operational capacities, tailored for both high and low-pressure applications. It is crucial to consider factors such as the valve's size, endurance against temperature variations, and compatibility with the fluids in your system. Furthermore, designs that incorporate spring-assisted mechanisms tend to provide improved sealing capabilities, reducing the risk of leaks and maintaining a consistent flow direction. In summary, the most effective Teflon check valves combine durability, efficiency, and compatibility, making them essential components for optimal system performance.

When it comes to installing and maintaining Teflon check valves, understanding the nuances of the process can significantly enhance performance and longevity. Teflon, known for its chemical resistance and low friction properties, is a great choice for industries dealing with corrosive fluids. According to a recent industry report by the Fluid Handling Research Institute, 75% of valve failures can be traced back to improper installation and maintenance practices, making it critical to adhere to best practices.

When installing Teflon check valves, ensure that the valve orientation matches the flow direction indicated on the body. Misalignment can lead to backflow problems and increased wear on seals, ultimately reducing the valve's lifespan. Additionally, it’s essential to use the correct torque specifications when tightening the valve to prevent leaks and over-tightening, which could crack the Teflon material.

For maintenance, regular inspections are vital. Check for signs of wear, leakage, or build-up of debris that can impede functionality. Cleaning the exterior of the valve periodically, without using abrasive materials, will help maintain its performance. The American Society of Mechanical Engineers (ASME) recommends conducting a thorough maintenance check every six months to one year, depending on the valve's usage conditions. By following these tips, you can optimize the performance of Teflon check valves and extend their reliable service life in your system.

This chart displays the flow rate efficiency of the top 5 Teflon check valves based on performance metrics. The values represent flow rates in liters per minute (L/min) under standard testing conditions.

Teflon check valves are widely used in many industrial applications due to their excellent chemical resistance and ability to handle corrosive fluids. However, like all mechanical devices, they can encounter issues that may compromise their performance. One common problem with Teflon check valves is leakage, which often results from improper installation or wear and tear over time. According to a report by the Fluid Power Journal, about 30% of check valve failures are attributed to incorrect alignment and lack of maintenance, highlighting the need for proper installation and regular inspection routines.

Another frequent issue is sticking, which can occur due to debris accumulation or chemical degradation of the valve components. A study by the National Institute of Standards and Technology found that Teflon materials, while resilient, can still deteriorate under extreme temperatures and aggressive chemical environments. To troubleshoot these problems, it's crucial to regularly flush the system to prevent debris buildup, and to check the valve's operational temperature range to ensure it remains within specifications. Furthermore, employing a proactive maintenance strategy can significantly enhance the longevity and performance of Teflon check valves, ensuring they operate effectively in their intended applications.

| Valve Model | Material | Size (inches) | Pressure Rating (PSI) | Temperature Range (°F) | Common Issues | Troubleshooting Tips |

|---|---|---|---|---|---|---|

| Model A | PTFE | 1/2 | 150 | -20 to 400 | Leakage | Check seals and tighten connections |

| Model B | Modified PTFE | 3/4 | 200 | -4 to 392 | Sticking | Inspect for debris and clean regularly |

| Model C | Carbon-filled PTFE | 1 | 300 | -40 to 450 | Failure to close | Ensure proper alignment and part integrity |

| Model D | PTFE with Bronze | 1.5 | 250 | -10 to 400 | Corrosion | Regular inspection for wear and replace as needed |

| Model E | Glass-filled PTFE | 2 | 150 | 0 to 400 | Wear and tear | Keep operating conditions within specified limits |