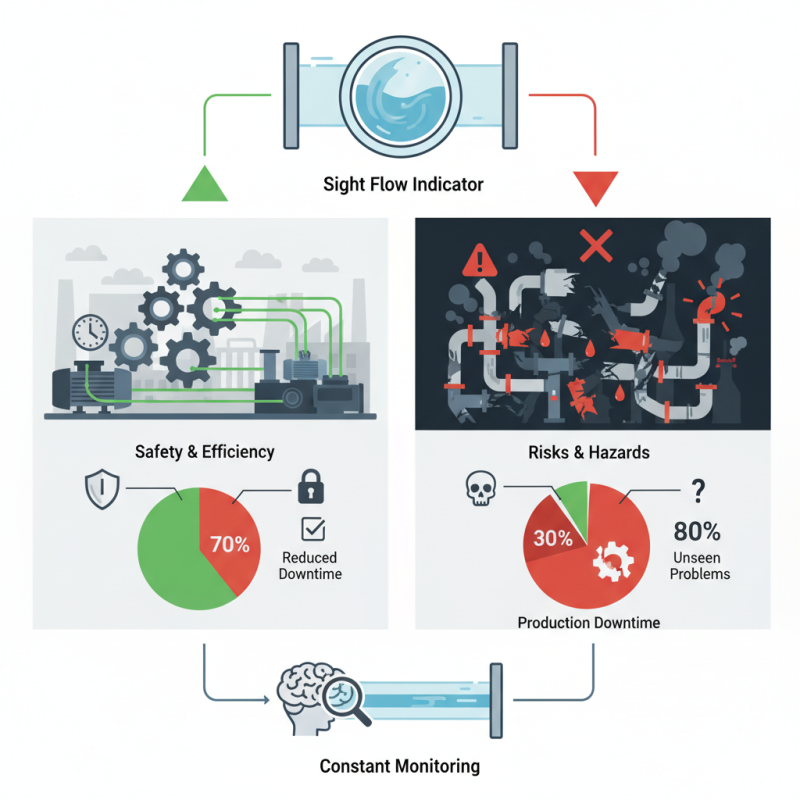

A sight flow indicator serves a crucial role in various industries, providing visual confirmation of fluid movement. In the chemical and oil sectors, for example, this device ensures safety and efficiency. According to a recent report by the Fluid Controls Institute, nearly 30% of production downtime can be attributed to flow inconsistencies. Observing these conditions in real time can mitigate risks significantly.

"Eighty percent of operational issues arise from unseen flow problems," says Dr. Sarah Thompson, an expert in fluid dynamics. Her insights emphasize the importance of using a sight flow indicator. Companies cannot afford to overlook such a seemingly simple tool in their operational strategy. Without proper flow monitoring, businesses risk inefficiencies and potential hazards.

Maintaining the integrity of flow is not just about reliance on complex systems. It often involves ensuring that basic tools like sight flow indicators are working correctly. Some facilities may find they lack sufficient visual cues, leading to unexpected equipment failures. The need for constant monitoring cannot be overstated. Ignoring these small details can lead to grave consequences in high-stakes environments.

A sight flow indicator is a vital tool used to observe the flow of liquids and gases in various systems. It consists of a transparent tube or window that allows users to visually assess the direction and flow rate of the medium. Operators can quickly determine if the flow is adequate or if there are blockages. This self-monitoring feature prevents potential damage to equipment.

Tips: When installing a sight flow indicator, ensure it is placed in a well-lit area. Good lighting improves visibility. Regular cleaning is also crucial. Dirt or residue can obscure the view, leading to misjudgments.

In industrial settings, a sight flow indicator helps maintain efficiency. However, it’s important to acknowledge that these devices can sometimes be misleading. For example, bubbles in a liquid can appear as flow interruptions. Users should be trained to interpret the readings accurately. Proper training minimizes mistakes and enhances safety.

Remember, a sight flow indicator is just one tool among many. Relying solely on it could be a mistake. Always combine visual observations with other measurement methods for better accuracy. This holistic approach ensures optimal operation of systems.

Sight flow indicators are crucial in various industries. They help monitor fluid movement in pipes and tanks. These indicators allow operators to see the flow of liquids or gases. This visibility can prevent costly mistakes. In many cases, human eyes are the best tool for immediate feedback.

Applications are widespread. Chemical plants use them to ensure continuous flow. Water treatment plants rely on them for safety. Food industries also benefit, ensuring ingredients move correctly through systems. However, these indicators are not foolproof. If not maintained, they can provide inaccurate readings. Regular checks are essential to avoid mishaps.

Users need to be aware of potential limitations. Sometimes, visibility can be obstructed by debris. This complicates fast decision-making. Operators must balance reliance on these instruments with good judgment. It’s a blend of technology and human intuition. Always questioning the reliability of sight flow indicators is wise. This mindset enhances safety and efficiency in operations.

A sight flow indicator is a vital tool in various industries. It allows operators to visually monitor the flow of liquids or gases. The simplicity of its design makes it effective in many applications. But how does it function mechanically?

Sight flow indicators typically consist of a transparent tube or window. As the fluid moves through the indicator, its movement is visible to the naked eye. The mechanical components include seals and gaskets that ensure no leakage occurs. These parts need regular inspection. If they wear out, they might lead to failures.

When fluid flows, its speed and clarity can reveal important information. Observing the flow can help identify potential issues, like blockages or contamination. However, relying solely on sight can be misleading. Sometimes, the flow may look fine, but underlying problems exist. Regular maintenance and calibration are essential for accurate readings. This ensures that operators have confidence in the indicators.

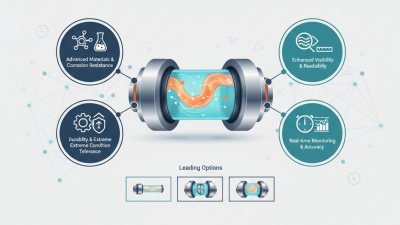

Sight flow indicators play a crucial role in various industries. They allow operators to visually monitor fluid movement through pipes. There are several types of sight flow indicators available in the market. Each type is designed for specific applications. They vary based on material, visibility, and flow rate capacity.

One common type is the glass sight flow indicator. It provides clear visibility of the fluid inside. However, glass can break easily. This poses a risk in high-pressure systems. On the other hand, plastic indicators are lightweight and do not shatter. Yet, they may not be suitable for high-temperature fluids. Metal indicators offer durability but can be opaque. Operational safety is often a concern when selecting the appropriate type.

According to industry reports, the demand for sight flow indicators is expected to grow by 5% annually. This increase is driven by expanding industrial activities. Many manufacturers are focusing on improving the design and efficiency of flow indicators. Enhanced visibility and safety features are vital for operators. However, companies sometimes overlook the importance of regular maintenance. Neglected indicators can lead to inaccurate readings and hazardous conditions. Operators need to ensure they select the right type and maintain it properly.

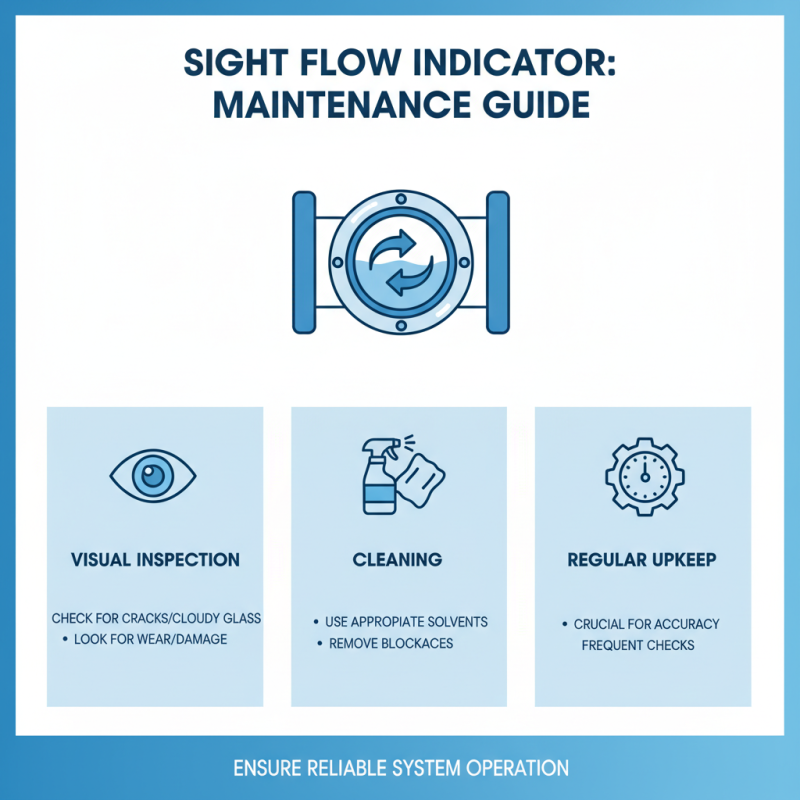

Sight flow indicators are essential components in fluid systems, providing visual cues about the flow of liquids and gases. Regular maintenance is crucial for accurate readings. Check for signs of wear or damage frequently. Small cracks or cloudiness in the glass can mislead operators. Cleaning should be done with appropriate solvents. Make sure the indicator is free from any blockages.

Troubleshooting is important when issues arise. If the flow indicator shows no movement, inspect the downstream valves. They may be closed or malfunctioning. A more serious problem could be an air bubble trapped within the system. In such cases, it’s essential to bleed the line carefully. Listening for unusual noises while in operation may also provide clues. Sometimes, it's simply a matter of recalibrating or adjusting the angle of the indicator.

Regular inspection helps prevent larger problems. Each sight flow indicator should be logged for performance issues. Sometimes users forget to document the maintenance schedule. This oversight can lead to unexpected failures. Keeping detailed records could help identify recurring issues. Use these notes for future reference and improvements.