The efficient management of fluid systems plays a crucial role in various industries, significantly impacting operational costs and productivity. According to a recent industry report by Grand View Research, the global industrial valve market is projected to reach $96.5 billion by 2025, with check valves being a prominent segment due to their essential function in preventing backflow. Among these solutions, the innovative lined check valve has emerged as a key player, offering enhanced durability and resistance to corrosion and wear. These advanced valves not only maximize efficiency but also extend service life, resulting in reduced maintenance costs and downtime. As industries increasingly seek sustainable and cost-effective solutions, the adoption of lined check valves is anticipated to rise, driving improved performance in fluid systems across various applications. Embracing these innovations can provide a competitive edge, ultimately leading to significant benefits for companies navigating the complexities of fluid management.

Traditional check valve designs often fall short in optimizing fluid efficiency due to several inherent challenges. One primary issue is the prevalence of turbulence caused by suboptimal flow paths within these valves, which can lead to significant energy loss. According to a report by the American Society of Mechanical Engineers (ASME), turbulent flow can increase pressure drop by up to 30%, adversely impacting the overall efficiency of fluid systems. Furthermore, traditional designs frequently suffer from wear and tear, leading to leakage or failure over time. A study cited in the International Journal of Fluid Mechanics suggests that unmitigated valve wear can reduce fluid flow rates by as much as 15%, ultimately compounding operational costs and maintenance needs.

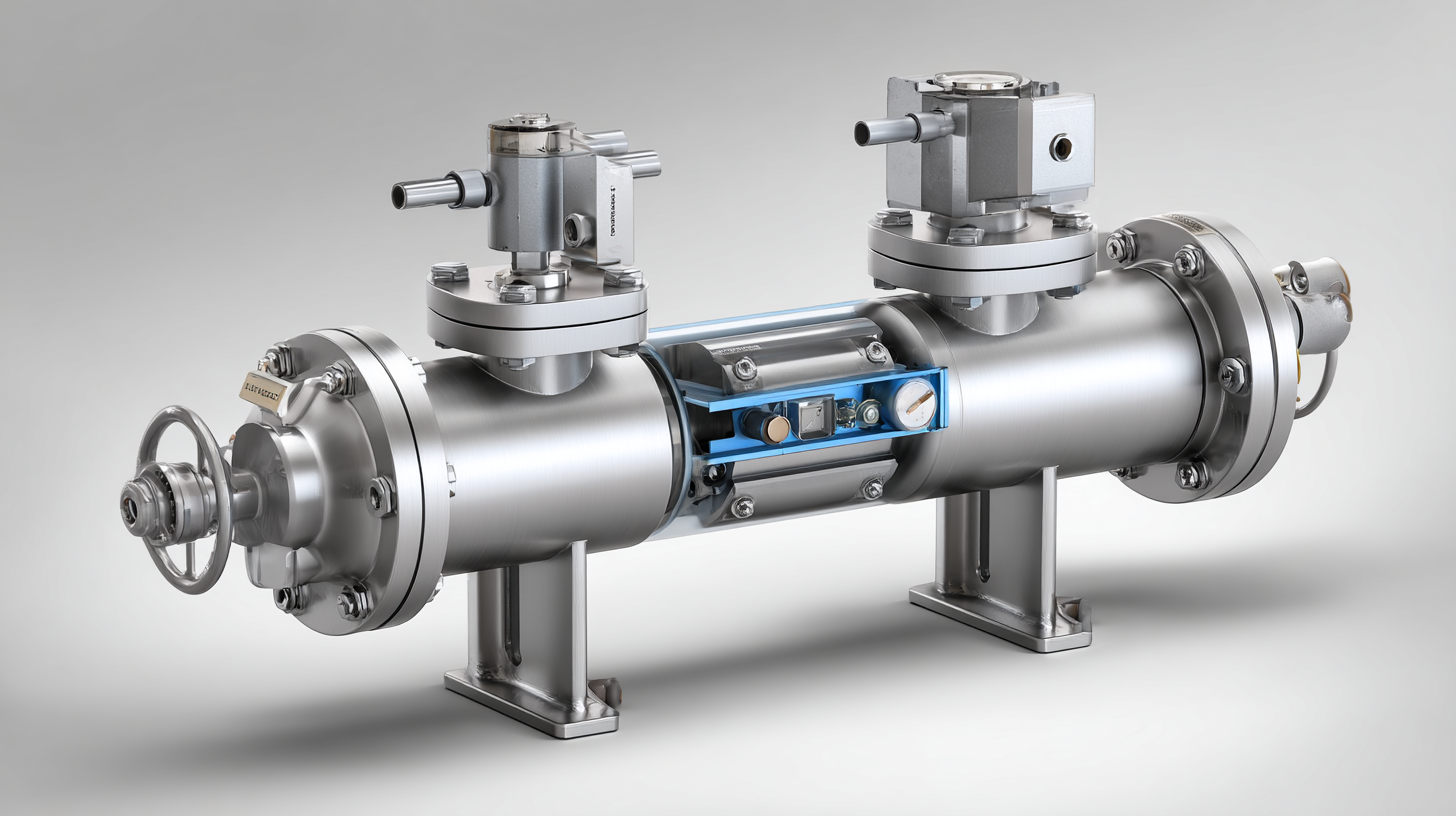

Innovative lined check valve solutions address these challenges by incorporating advanced materials and engineering techniques that promote streamlined flow and enhanced durability. For instance, the use of polymer linings can significantly reduce friction and prevent erosion, yielding an estimated efficiency improvement of up to 25% in fluid conveyance systems. As reported by the Fluid Control Institute, adopting these innovative check valve designs not only minimizes energy loss but also extends the lifespan of critical components, thereby offering a compelling return on investment for industries that rely heavily on fluid management.

The integration of lined check valve technology has become pivotal in optimizing flow dynamics and reducing pressure drops within fluid systems. Recent studies indicate that traditional check valves can lead to significant energy losses due to turbulence and restricted flow paths. By incorporating innovative lining materials, such as PTFE or rubber, manufacturers have successfully minimized these adverse effects. A report from the American Society of Mechanical Engineers (ASME) suggests that modern lined check valves can reduce pressure drops by up to 30%, allowing for more efficient system performance and greater energy savings.

Additionally, the enhanced sealing properties of lined check valves play a crucial role in maintaining flow stability. Data from the Flow Research Institute indicates that in systems where lined check valves are implemented, flow transitions have demonstrated a reduction in cavitation occurrences by approximately 25%. This capability not only protects system integrity but also extends the lifespan of upstream and downstream components. As industries increasingly focus on sustainability and cost efficiency, the adoption of lined check valve solutions stands out as a beneficial strategy for optimizing fluid handling processes.

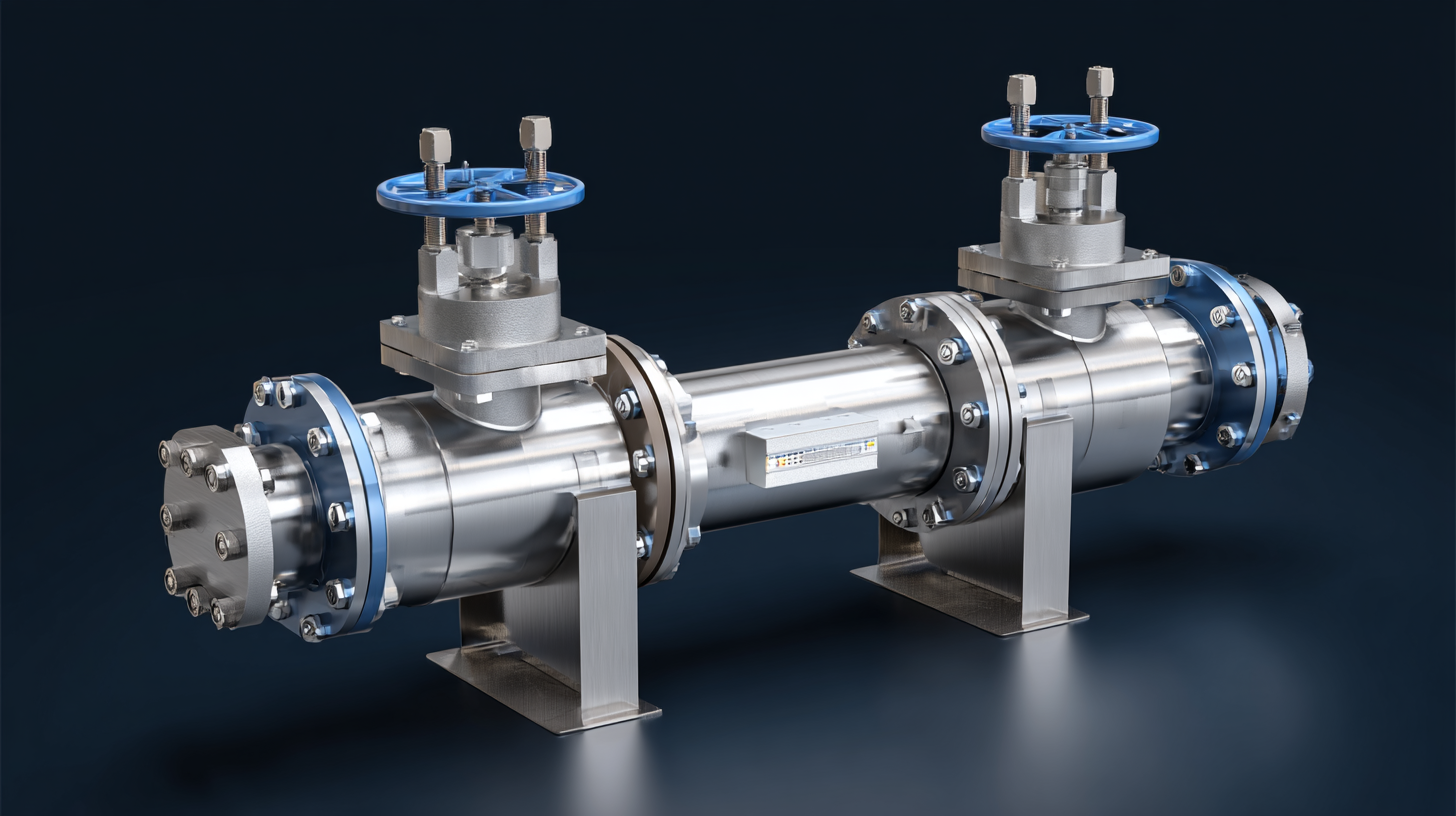

In various industrial applications, the choice between lined and unlined check valves can significantly impact system efficiency and longevity. Lined check valves, coated with protective materials, offer enhanced resistance to corrosive fluids and can reduce maintenance costs over time. They are often preferred in industries such as chemical processing and wastewater management, where harsh environments are prevalent. On the other hand, unlined check valves, while usually more cost-effective, may require more frequent replacements and repairs if subjected to aggressive substances.

Tip: When selecting a check valve, consider the fluid type and operating conditions to ensure optimal performance. Conducting a thorough analysis of the environment can guide you toward the best material choice for your specific application.

Furthermore, the installation and operation of lined check valves often lead to a lower risk of leaks and failures. Their design minimizes turbulence and ensures a smooth flow of fluids, which is essential in maintaining system efficiency. Conversely, unlined versions may be more susceptible to wear and tear, which can compromise the integrity of fluid systems.

Tip: Regular inspections and maintenance schedules can help identify potential issues before they escalate, particularly in systems utilizing unlined check valves, where the wear rate is higher.

Advancements in materials technology have paved the way for improved performance in lined check valves, which are vital components in various fluid systems. By integrating advanced materials such as high-density polyethylene (HDPE) or fluoropolymers, manufacturers have significantly enhanced the durability of these valves. These materials not only resist corrosion and abrasive wear but also withstand extreme temperatures and pressures, ensuring a longer operational lifespan.

Moreover, the incorporation of innovative lining technologies allows for better sealing and reduced turbulence within the fluid systems. This improvement leads to increased efficiency and reduced energy consumption during operation. Enhanced performance characteristics, such as minimized leakage rates and superior flow dynamics, contribute to the overall reliability and effectiveness of fluid control systems across diverse industries, from chemical processing to water treatment. As industries continue to evolve, the role of advanced materials in lined check valves remains crucial in meeting the demanding challenges of modern fluid management.

When it comes to optimizing fluid systems, implementing lined check valve solutions is a game changer. These innovative devices not only enhance flow efficiency but also provide resistance against corrosion and buildup, ultimately extending the lifespan of your system. However, integrating these valves requires careful consideration of best practices to maximize their benefits.

When it comes to optimizing fluid systems, implementing lined check valve solutions is a game changer. These innovative devices not only enhance flow efficiency but also provide resistance against corrosion and buildup, ultimately extending the lifespan of your system. However, integrating these valves requires careful consideration of best practices to maximize their benefits.

One crucial tip is to assess the specific needs of your existing system before installation. Consider factors such as the type of fluid being transported, pressure conditions, and the existing construction materials. This will ensure compatibility and performance reliability. Additionally, regular maintenance checks should be scheduled to identify any wear that might impact the valve's functionality.

Another best practice involves training personnel on the proper usage and maintenance of lined check valves. Educating your team about the operational principles and common issues can prevent mishaps and promote a smoother workflow. Implementing a routine inspection and replacement protocol will safeguard against unexpected failures and preserve system efficiency for years to come.