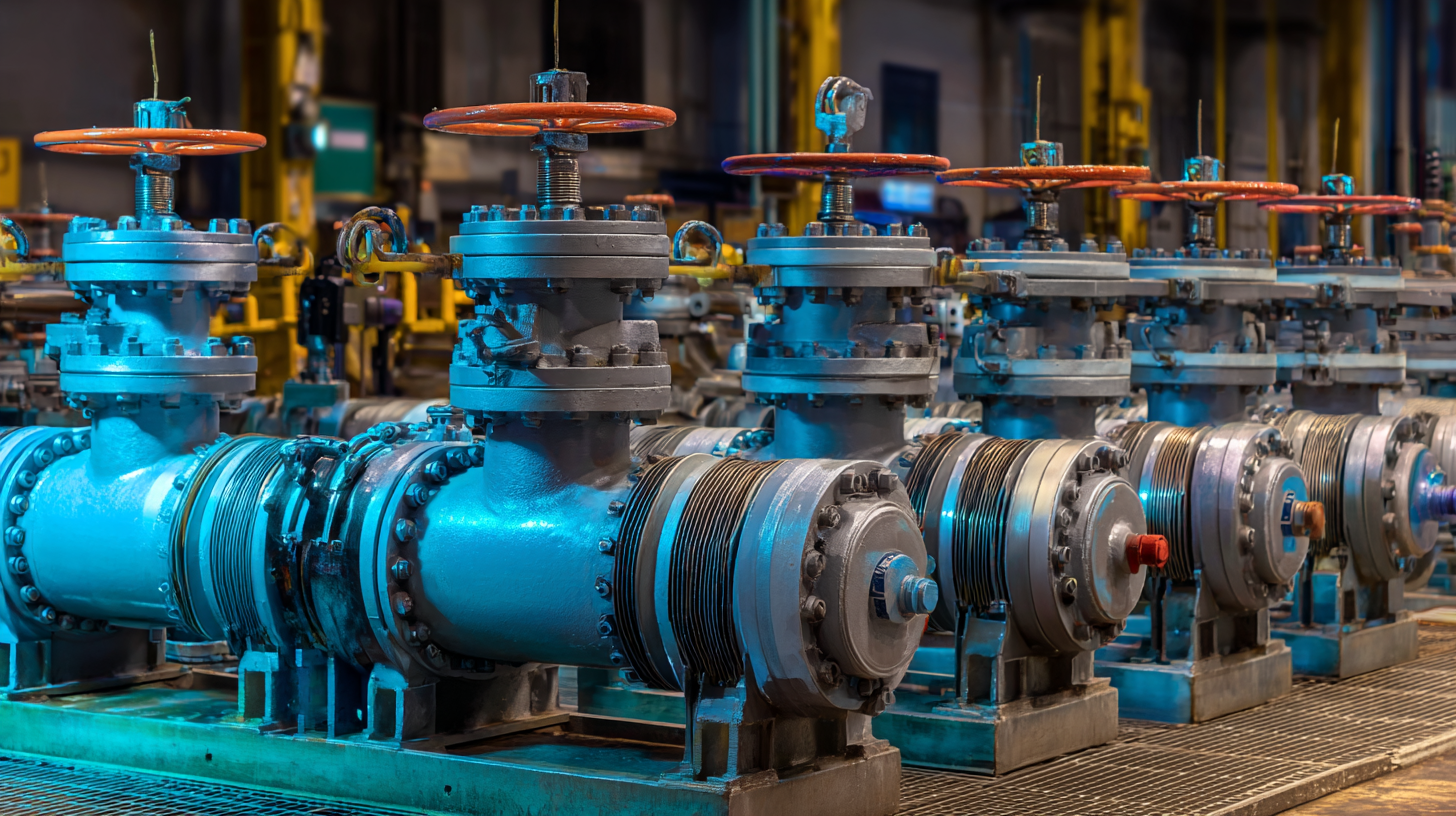

In the ever-evolving landscape of industrial applications, the importance of sourcing high-quality lined valves cannot be overstated. As 2023 unfolds, manufacturers and engineers alike are faced with the challenge of selecting the best lined valves that ensure durability, efficiency, and compatibility with various fluids. This blog aims to provide you with 10 essential tips for sourcing lined valves that meet the increasing demands of modern industries. By focusing on key factors such as material selection, performance standards, and supplier reputation, you can make informed decisions that enhance operational reliability. Whether you are involved in chemical processing, water treatment, or any other application requiring lined valves, our insights will guide you through the complexities of the procurement process, helping you to identify the best options available in the market today.

The lined valve market is experiencing significant growth, driven by the increasing demand for corrosion-resistant solutions across various industries. According to a recent report by MarketsandMarkets, the global lined valve market is projected to reach USD 1.7 billion by 2025, expanding at a CAGR of 5.4% from 2020. This growth is primarily attributed to the rising adoption of lined valves in chemical processing, oil and gas, and water treatment applications, where harsh operating conditions necessitate reliable and durable equipment.

Key trends shaping the lined valve market in 2023 include the integration of advanced materials and technologies. Innovative lined valve designs that feature enhanced resistance to chemicals and extreme temperatures are gaining traction among end-users seeking longevity and safety. Additionally, as sustainability becomes a focal point, manufacturers are increasingly focusing on eco-friendly materials and production processes. A report by Grand View Research highlights that the increasing emphasis on reducing environmental impact in industrial operations will further propel the adoption of lined valves, positioning them as essential components for future industrial applications.

When sourcing lined valves in 2023, it’s crucial to focus on essential specifications that ensure optimal performance and compatibility for your application. The material used in the construction of lined valves is paramount, as it directly affects the valve's resistance to corrosion, wear, and chemical compatibility. Common lining materials such as fluoropolymers, rubber, and ceramic should be considered based on the specific medium being transported and the operating environment. Evaluating the compatibility of these materials with the process fluids is key to enhancing the longevity and reliability of the valve.

In addition to material selection, pressure ratings play a vital role in determining the suitability of lined valves for your system. It is essential to select valves that meet or exceed the maximum pressure requirements of your application. Pressure ratings typically range from low to high, and mismatched ratings can lead to valve failure and operational hazards. Furthermore, adhering to industry standards—such as ANSI/ASME or API—ensures that the lined valves conform to both safety and performance benchmarks.

Understanding these specifications will not only aid in effective sourcing but also contribute to the overall efficiency and safety of your operations.

When sourcing lined valves in 2023, evaluating supplier credentials is paramount to ensuring both product quality and reliability. Start by assessing the manufacturer's industry experience and specialization. A company with a long history in producing lined valves is more likely to understand the nuances of the materials and coatings involved, leading to better performance and durability. Furthermore, ensure that the manufacturer adheres to recognized quality standards, such as ISO certification, which demonstrates a commitment to maintaining high production practices.

In addition to industry experience, it’s crucial to investigate the manufacturer’s technical capabilities and innovation. Look for suppliers that invest in research and development, as this can be a strong indication of their commitment to evolving their product offerings. Examine customer testimonials and case studies to gauge satisfaction levels and the manufacturer’s ability to meet specific needs. Lastly, consider their customer service and support. A responsive supplier who offers technical assistance and is willing to collaborate on tailor-made solutions can make a significant difference in your sourcing experience.

| Criteria | Description | Importance Level | Rating Scale |

|---|---|---|---|

| Quality Certifications | Check for ISO and other relevant certifications to ensure quality assurance. | High | 1-5, with 5 being excellent |

| Experience in Industry | Evaluate the supplier's years of experience in manufacturing lined valves. | Medium | 1-5, with 5 being highly experienced |

| Technical Support | Assess the availability and expertise of their technical support team. | High | 1-5, with 5 being top-notch |

| Product Range | Diversity of lined valve types and sizes offered. | Medium | 1-5, with 5 being a wide range |

| Customer Reviews | Research customer feedback and ratings from past clients. | High | 1-5, with 5 being highly rated |

| Pricing Transparency | Ensure clear and detailed pricing with no hidden costs. | Medium | 1-5, with 5 being very transparent |

| Lead Time | Understand the average lead times for orders and deliveries. | High | 1-5, with 5 being very reliable |

| After-Sales Service | Look for a solid after-sales support framework to address issues. | High | 1-5, with 5 being exceptional |

| Sustainability Practices | Investigate the manufacturer's commitment to eco-friendly practices. | Medium | 1-5, with 5 being highly sustainable |

| Location | Consider proximity to reduce shipping time and costs. | Low | 1-5, with 5 being locally available |

When sourcing lined valves in 2023, it is crucial to conduct a thorough cost analysis that extends beyond the initial purchase price. Understanding the total cost of ownership (TCO) is essential for making informed procurement decisions. This includes evaluating maintenance costs, installation costs, and the long-term performance of the valves. With many industries pivoting towards materials that offer enhanced durability, such as those resistant to seawater corrosion, particularly in marine applications, the initial investment should be weighed against future savings and reliability.

Furthermore, the discussion around the TCO of lined valves can benefit from insights gained from water utilities' experiences with service line replacements. Regulatory mandates requiring the safe delivery of water necessitate financial responsibility, prompting utilities to carefully consider not only their upfront costs but also ongoing operational expenses. This approach can serve as a best practice model for industries reliant on lined valves, ensuring that they choose solutions that not only meet current functional requirements but also contribute to a sustainable and cost-effective long-term strategy.

As the demand for eco-friendly solutions increases, sourcing lined valves with sustainability in mind is crucial for industries aiming to reduce their environmental impact.

One of the key considerations is the choice of materials used in the manufacturing process. Opting for valves made from recycled or sustainably sourced materials not only lowers the carbon footprint but also ensures compliance with environmental regulations. Certifications such as ISO 14001, which focuses on effective environmental management systems, provide a benchmark for manufacturers committed to sustainable practices.

In addition to material selection, it is essential to consider the durability and longevity of lined valves. Investing in high-quality products that can withstand harsh conditions will minimize waste over time. Furthermore, look for suppliers that prioritize eco-friendly manufacturing processes and offer transparent information about their environmental practices. This transparency allows businesses to make informed choices that align with their sustainability goals while promoting responsible sourcing within the industry. Embracing these eco-friendly options not only benefits the environment but also enhances the reputation of a brand committed to sustainable industrial practices.