Choosing the right fluid level gauges is crucial for efficient operations. These devices help monitor liquid levels accurately in various applications. With numerous options available, making the right decision can be daunting.

Consider the specifics of your application. Different industries may require unique features from fluid level gauges. For instance, some might need gauges that withstand harsh environments. Others may prioritize precision over durability. Understanding your unique requirements is vital.

It is essential to evaluate the quality and reliability of the gauges. Research brands and their reputations. Read user reviews and experiences. Sometimes, even a small factor can make a big difference in performance. Mistakes in choosing can lead to costly downtime. Taking the time to reflect on your needs is crucial. Make informed choices to enhance productivity and safety.

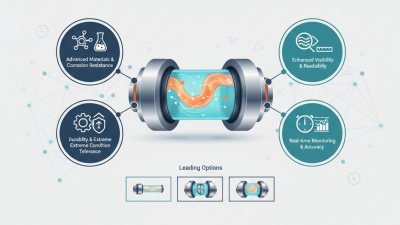

Fluid level gauges play a critical role in various industries, including oil and gas, water treatment, and pharmaceuticals. Understanding the types of gauges is essential for making informed choices. There are several types of fluid level gauges, such as mechanical, electronic, and optical models, each serving unique needs. According to a 2022 report by Market Research Future, the fluid level gauge market is projected to grow at a CAGR of 6.5% from 2022 to 2030. This increase signals a growing demand for accurate and reliable measurement solutions.

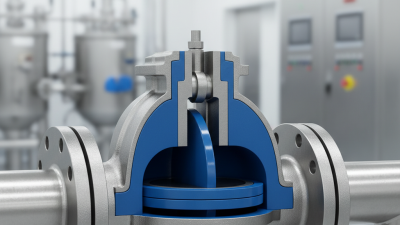

Mechanical gauges are often favored for their simplicity. They require no external power and are robust in nature. Electronic gauges, on the other hand, offer enhanced precision and data tracking capabilities. However, they can be more complex to install and maintain. Optical gauges provide visual confirmation of fluid levels but may not perform well in certain environments. Trade-offs exist among these types, and choosing the wrong gauge can lead to costly errors.

It's important to reflect on specific application requirements. For example, a corrosive environment might rule out some materials used in certain gauges. Accurate assessments of factors like temperature and pressure are also vital. Inadequate sizing and incorrect integration can compromise functionality. Therefore, understanding various fluid level gauges is key to optimizing their application and ensuring operational efficiency.

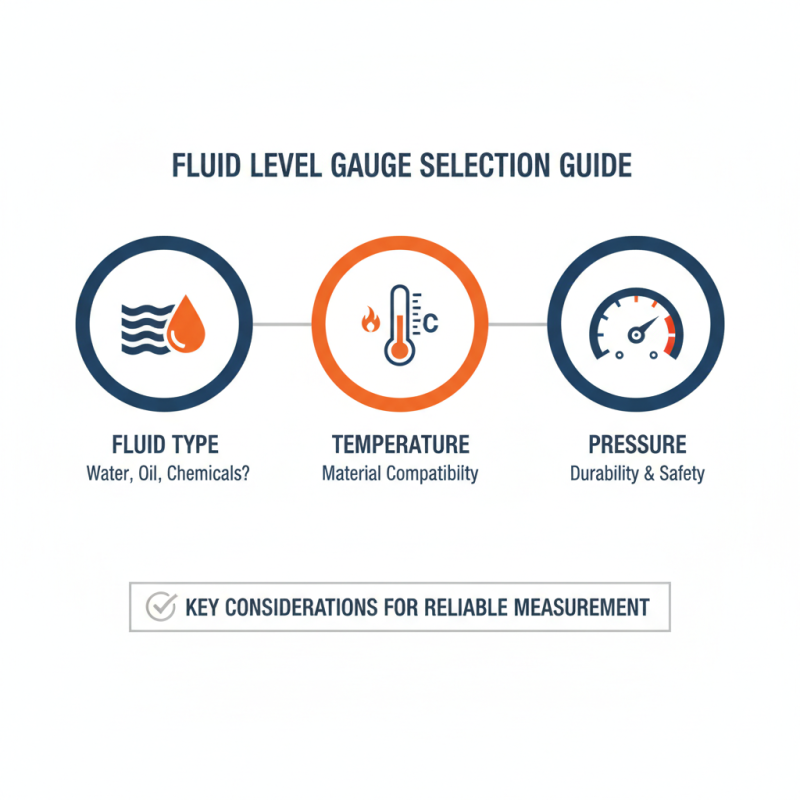

When selecting fluid level gauges, several key factors come into play. Understanding the type of fluid involved is crucial. Different fluids, like water or oil, require different gauge technologies. The temperature and pressure conditions affect material compatibility. A gauge that works for one fluid might fail with another.

Consider the installation environment. Harsh conditions, like high humidity or extreme temperatures, can impact gauge performance. The size of the tank also matters. A small tank may not require complex gauges, while large tanks often need advanced features. Evaluate the visibility of the readout. A gauge that’s hard to read isn’t useful.

Don’t overlook maintenance needs. Some gauges require regular calibration, while others are nearly maintenance-free. Easy access for servicing is a plus. Think about your budget too. A cheaper option might save money upfront but could lead to higher costs later. Weighing immediate savings against long-term reliability is necessary.

When evaluating accuracy and reliability in fluid level measurement, certain factors come into play. Precision is key. An accurate gauge can save time and prevent costly spills. Always check the manufacturer's specifications. They should detail accuracy levels. Understand the operating conditions as well. High temperatures or pressures may affect performance.

Choose a gauge designed for your specific fluid. Different fluids require different materials. For example, corrosive liquids need specialized gauges. These can withstand harsh environments. This choice impacts both reliability and lifespan.

Another tip is to consider the installation location. Accessibility for maintenance is crucial. Gauges in hard-to-reach spots can lead to neglect. Regular checks are essential for long-term accuracy. Evaluate how often the gauge needs calibration. Frequent calibration may indicate an underlying issue. Remember, what works for one application may not suit another. Make informed choices to achieve the best results.

| Tip No. | Criteria | Importance Level | Recommended Measurement Range | Common Applications |

|---|---|---|---|---|

| 1 | Evaluate Measurement Accuracy | High | 2 - 100 ft | Water Tanks |

| 2 | Consider Environmental Conditions | Medium | 0 - 50°C | Chemical Storage |

| 3 | Assess Reliability | High | 15 - 120 ft | Oil Storage |

| 4 | Review Installation Requirements | Medium | Varied | Industrial Tanks |

| 5 | Check for Regulatory Compliance | High | N/A | Pharmaceuticals |

| 6 | Evaluate Cost vs. Value | Medium | N/A | Beverage Industry |

| 7 | Research Maintenance Needs | Medium | Varied | Wastewater Treatment |

| 8 | Look for Advanced Features | Low | N/A | Marine Applications |

| 9 | Inquire About Warranty | High | N/A | Agricultural Use |

| 10 | Read User Reviews | Medium | N/A | General Purpose |

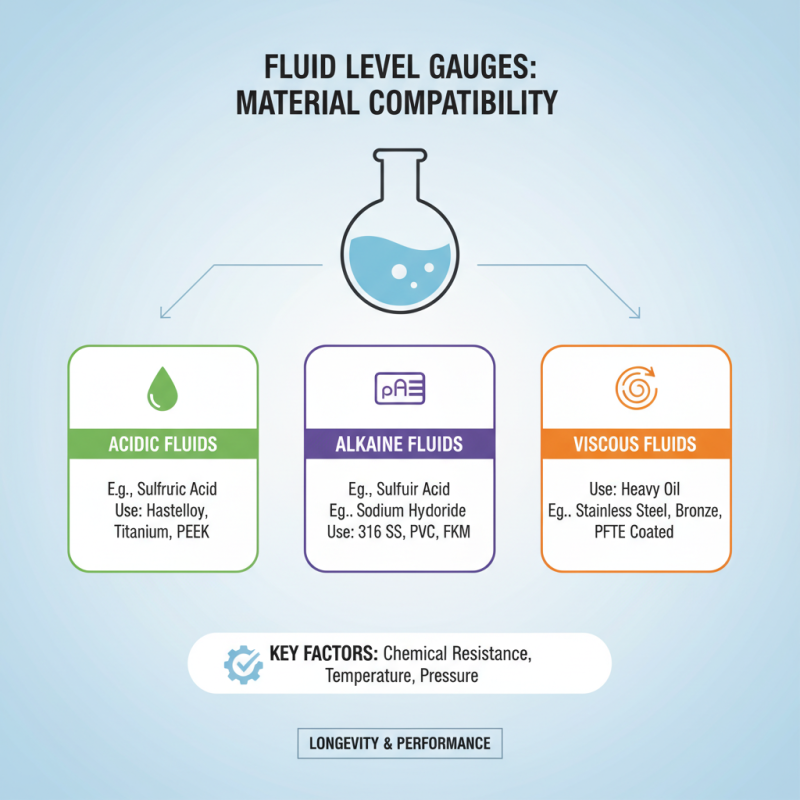

When selecting fluid level gauges, material compatibility is crucial for longevity and performance. Each gauge must withstand the fluid's chemical properties. Consider the type of fluid your gauge will interact with. Will it be acidic or alkaline? Is it a viscous liquid? Identifying these factors helps in choosing the right material.

For example, stainless steel is often a suitable choice for many fluids, but not all. Some corrosive substances can damage it, leading to leaks or gauge failure. If unsure, consult with material experts. They can provide insight into the best materials for your specific needs.

Tip: Always request samples or prototypes to test compatibility before full-scale installation. This small step can save significant costs later. Test in real-world conditions. This ensures the gauge performs as expected. Taking these precautions can prevent costly repairs and downtime. Remember, the right material makes a significant difference.

When selecting fluid level gauges, budget considerations are crucial. Cost-effective solutions can significantly impact project viability. According to a 2022 industry report, companies can reduce expenses by up to 35% by choosing the right equipment. This number highlights the importance of thorough financial planning.

Cheaper options may seem tempting. However, it’s essential to consider long-term performance and reliability. A study indicated that low-quality gauges often require replacements more frequently, increasing overall costs. Monitoring your total cost of ownership may help in making informed choices. Remember, investing in quality now can save money later.

Many suppliers offer various budget-friendly options. Evaluate the specifications carefully. Some low-cost alternatives may not provide accurate readings. Balancing initial costs with quality and longevity is vital. Critically assess how the gauge fits your specific application. This often involves endless questions and reflections on past experiences. In some cases, overspending on features that aren’t necessary could lead to regrets later.