In the world of fluid control systems, the selection of the right components is crucial for optimal performance and longevity. This is especially true when it comes to Teflon check valves. These valves are widely recognized for their resistance to corrosion and ability to handle a variety of chemicals, making them an indispensable choice for many applications. According to industry expert Dr. Emily Johnson, a leading authority in fluid dynamics, "Choosing the right Teflon check valve can significantly enhance system efficiency while minimizing maintenance costs."

In the world of fluid control systems, the selection of the right components is crucial for optimal performance and longevity. This is especially true when it comes to Teflon check valves. These valves are widely recognized for their resistance to corrosion and ability to handle a variety of chemicals, making them an indispensable choice for many applications. According to industry expert Dr. Emily Johnson, a leading authority in fluid dynamics, "Choosing the right Teflon check valve can significantly enhance system efficiency while minimizing maintenance costs."

As we approach 2025, the market for check valves continues to expand, and the options available can be overwhelming. With advancements in technology and material science, it is essential to understand what features to look for when selecting a Teflon check valve that suits your specific needs. Dr. Johnson emphasizes that "considering factors such as pressure ratings, flow characteristics, and chemical compatibility is vital to making an informed decision."

This guide will explore the top ten Teflon check valves of 2025, offering insights into their specifications and applications. By carefully considering the features and benefits of each option, you can ensure that your selection will lead to enhanced reliability and performance in your fluid control systems.

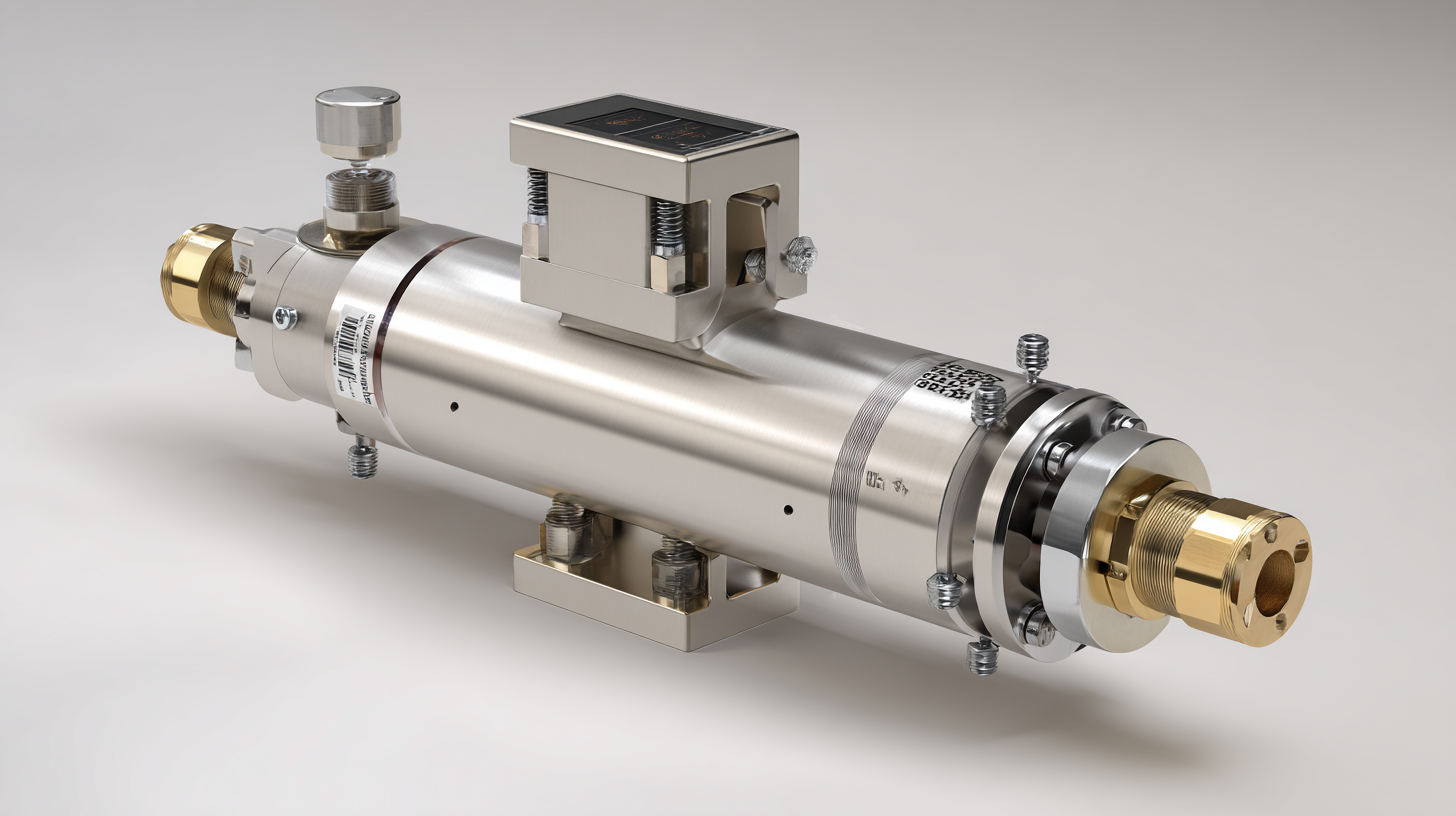

When selecting a Teflon check valve for your specific applications, it's essential to understand the various types available and their respective functionalities. Teflon check valves typically come in two main designs: swing check valves and lift check valves. Swing check valves utilize a disc that pivots on a hinge, allowing for efficient flow in one direction while preventing backflow. This design offers low-pressure drop and is suitable for applications where space is limited.

In contrast, lift check valves feature a movable disk that lifts off its seat to allow flow. This design is ideal for high-pressure systems but may require more space for installation.

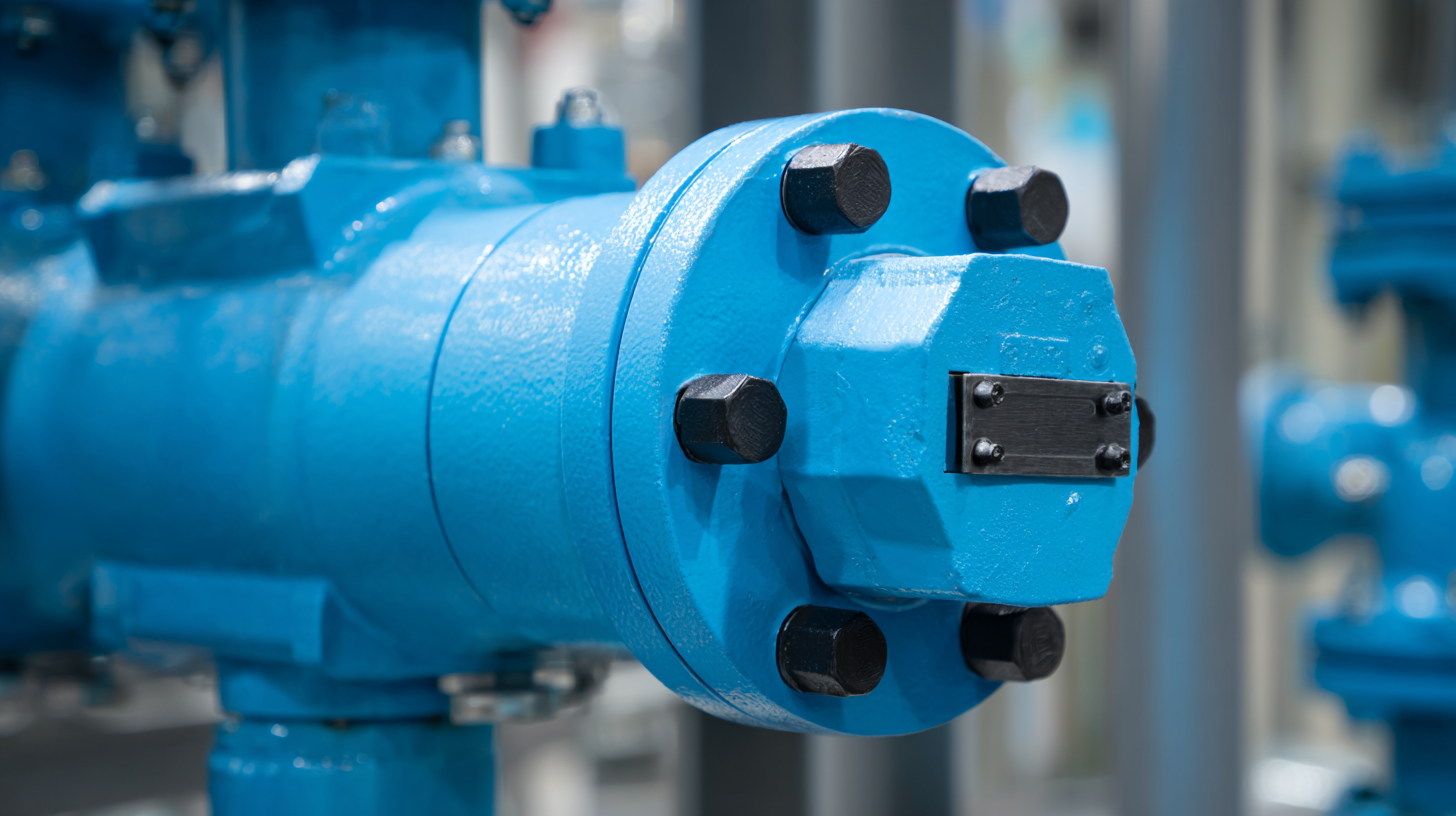

Each type of Teflon check valve excels in certain environments and applications. For instance, swing check valves are often used in water and wastewater treatment, as well as in chemical processing industries where fluid dynamics are a concern. On the other hand, lift check valves are commonly found in high-pressure steam systems, oil and gas applications, and situations where fluid changes direction frequently. Understanding these distinctions helps in selecting the right valve that not only meets the operational requirements but also ensures longevity and reliability in challenging chemical environments.

When selecting the best Teflon check valve for your application, it’s crucial to focus on key performance metrics that will determine the valve’s efficiency and longevity. One of the primary considerations is the pressure rating, which directly affects the valve’s ability to withstand operational pressures without leakage or failure. Understanding your system's maximum pressure requirements will help you select a valve that can handle those conditions effectively.

Another important metric is the temperature resistance of the Teflon material. Different applications operate within various temperature ranges, and using a valve that can withstand high or low temperatures is essential to prevent material degradation and ensure functionality over time. Furthermore, flow rate capacity should be assessed; a valve optimized for the expected flow can minimize turbulence and maximize efficiency. Considering these performance metrics will guide you in making an informed decision tailored to your specific operational needs.

| Performance Metric | Description | Standard Value | Recommended Range |

|---|---|---|---|

| Temperature Resistance | Maximum operating temperature the valve can withstand | 260°C | -50°C to 260°C |

| Pressure Rating | Maximum pressure the valve can handle without leakage | 150 psi | 0 to 150 psi |

| Flow Rate | Volume of fluid that can flow through the valve per unit time | 50 GPM | 1 to 50 GPM |

| Chemical Compatibility | The valve's suitability with different chemicals | Compatible with most chemicals | Refer to chemical compatibility chart |

| Installation Type | Type of installation method compatible with the valve | Threaded | Threaded, Flanged, Welded |

When selecting Teflon check valves for fluid systems, it’s crucial to consider industry standards and compliance. Teflon check valves, known for their chemical resistance and durability, must meet stringent guidelines outlined by organizations such as the American Society of Mechanical Engineers (ASME) and the American National Standards Institute (ANSI). According to a report by the Fluid Controls Institute, Teflon valves should conform to specifications that ensure they can withstand high pressures and temperatures while maintaining integrity under various chemical exposures.

Moreover, the compliance with an industry standard such as ISO 9001 is essential for ensuring consistent quality management. According to recent data from the International Organization for Standardization, over 1.7 million companies worldwide adhere to ISO 9001 standards, highlighting the global significance of these benchmarks in manufacturing processes, including the production of Teflon check valves. Businesses must assess the certification of their Teflon valve suppliers and verify that they adhere to these compliance standards to ensure reliability and safety in their fluid handling systems.

When selecting a Teflon check valve for your applications, it is essential to understand the materials and designs available, as they directly influence performance and longevity. Teflon, known for its excellent chemical resistance and low friction properties, is commonly used in applications demanding high purity and resistance to corrosive substances. According to a report from the Valve Manufacturers Association, Teflon check valves can withstand temperatures up to 260°C (500°F) and are impervious to a wide range of chemicals, making them an ideal choice for industries such as pharmaceuticals, food processing, and chemical manufacturing.

When comparing Teflon check valve designs, key factors include the valve's flow characteristics, leak tightness, and response time. Types like spring-loaded and ball type check valves have distinct advantages; for instance, ball type valves provide quick sealing, which is crucial in preventing backflow in critical processes. Studies by the American Society of Mechanical Engineers indicate that well-designed Teflon check valves can lead to a 25% increase in efficiency due to better flow management and minimized pressure loss. Understanding these material characteristics and design functions is fundamental to choosing the best Teflon check valve tailored to your operational requirements.

When selecting a Teflon check valve for specific applications, understanding its lifespan and maintenance requirements is crucial. According to a report from the Fluid Controls Institute, Teflon check valves can typically last between 5 to 15 years, depending on the operating environment and frequency of use. High-temperature or corrosive environments, often found in industrial settings, may accelerate wear and tear, significantly impacting valve longevity. Consequently, industries must evaluate their operational conditions to determine appropriate valve choices that align with expected service life.

In addition to lifespan, maintenance needs play a fundamental role in operational efficiency. Regular inspections and timely maintenance can prevent failures and ensure optimal performance. Data from the American Society of Mechanical Engineers (ASME) suggests that implementing a structured maintenance schedule can reduce unexpected downtime by up to 30%. This is particularly pertinent for sectors like pharmaceuticals and petrochemicals, where contamination risks can have severe consequences. Understanding both the lifespan and maintenance requirements of Teflon check valves enables organizations to minimize disruptions and maintain compliance with industry standards while ensuring that their systems operate smoothly.