Choosing the right fluid level gauges is crucial for various industries. Accurate fluid measurement impacts efficiency, safety, and productivity. According to a recent report by Market Research Future, the fluid level gauge market is projected to grow at a CAGR of 4.5% over the next five years. This growth is driven by advancements in technology and increasing demand for precision.

Expert John Smith, a leader in fluid measurement solutions, states, "Selecting the right fluid level gauge can make or break operational success." His insight highlights the importance of understanding different gauge types. Each type serves distinct functions and applications, raising questions about compatibility and accuracy.

Yet, many businesses still struggle with their fluid measurement choices. An unsuitable gauge can lead to inefficiencies and safety risks. It’s vital to evaluate your specific needs and environmental conditions before making a decision. The possibilities are vast, but not every gauge will be ideal for your operations. This reflects the necessity for careful consideration and expert advice in selecting the right fluid level gauges.

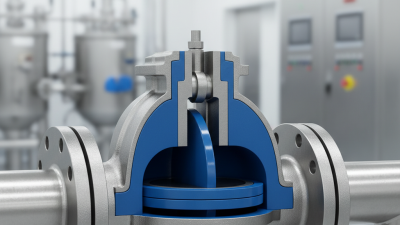

Fluid level gauges come in various types, each designed for specific applications. For example, mechanical gauges use floats to indicate levels. These are quite reliable in simple applications. However, they may not be ideal for complex scenarios, where accuracy is essential. Electronic gauges offer precision but can be more costly and require maintenance.

Understanding your needs is vital. Consider the environment. High temperatures or corrosive substances can damage certain types of gauges. Even some electronic devices might fail in extreme conditions. Think about installation as well. Some gauges fit easily into tight spaces; others demand more room. This can affect your choice significantly.

Installation and maintenance are also key here. Improper installation can lead to inaccurate readings. Regular checks are necessary for all gauges. Over time, mechanical parts wear out. Electronic components may experience failure too. Make a plan for inspections to ensure functionality. Ultimately, the right gauge is one that aligns with your specific requirements.

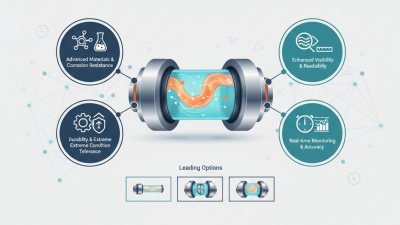

When selecting fluid level gauges, several key factors warrant attention. These factors ensure that the chosen gauge effectively meets your specific needs. Consider the type of fluid you will be measuring. Certain gauges work better with liquids, while others suit slurries or granules. Understanding your fluid's properties, such as viscosity and temperature, is crucial.

Accuracy is another essential factor. Look for gauges that provide reliable readings. A slight deviation can lead to operational issues. Also, think about the environment where the gauge will be used. Harsh conditions may require more durable, resistant materials.

**Tips:** Assess the installation space. Some gauges need more room than others. Consider safety features if working with hazardous materials. Evaluate whether electronic gauges might offer more advanced capabilities compared to traditional models. Always review the maintenance requirements. Some models may demand regular upkeep, making them less convenient for you.

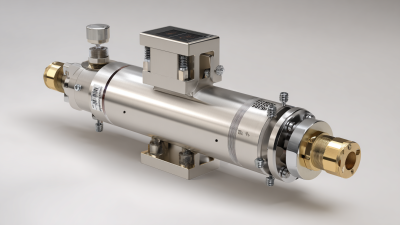

When choosing fluid level gauges, you face a critical decision: mechanical or electronic. Mechanical gauges use float mechanisms to measure levels. They have simple designs and no need for power. This can be advantageous in remote locations. However, they might struggle with accuracy in turbulent conditions. The mechanics can wear out over time, affecting reliability.

On the other hand, electronic fluid level gauges offer more precise readings. They employ sensors and digital displays. Their data can be easily integrated into automated systems. Yet, they require a power source, limiting their use in some environments. Battery life can be a concern. Additionally, the initial cost is typically higher than mechanical options.

Both types have pros and cons. Mechanical gauges are robust but may need periodic recalibration. Electronic gauges are sophisticated but can fail due to electrical issues. Your choice should align with specific needs. Consider your budget, environment, and the level of accuracy required. Each option has nuances, making it essential to research before deciding.

When selecting fluid level gauges, accuracy and reliability are paramount.

These factors ensure that measurements are precise, which is critical for various industries.

A miscalculation might lead to overflows or equipment failure, causing costly downtime.

Thus, aiming for gauges that exhibit a minimal margin of error is essential.

Understanding the measurement technology is crucial. Some gauges rely on pressure, while others use ultrasonic waves.

Each method has its strengths and weaknesses.

Pressure-based sensors can be affected by temperature changes, while

ultrasonic gauges may struggle in turbulent liquids.

Evaluating these nuances helps refine your choice.

Continuous monitoring of gauge performance is necessary. Regular calibration can mitigate inaccuracies over time.

It’s important to encourage feedback from system operators. They often notice inconsistencies before the gauges do.

Staying alert to these issues allows for a proactive approach.

Choosing the right gauge demands careful reflection and a willingness to adapt.

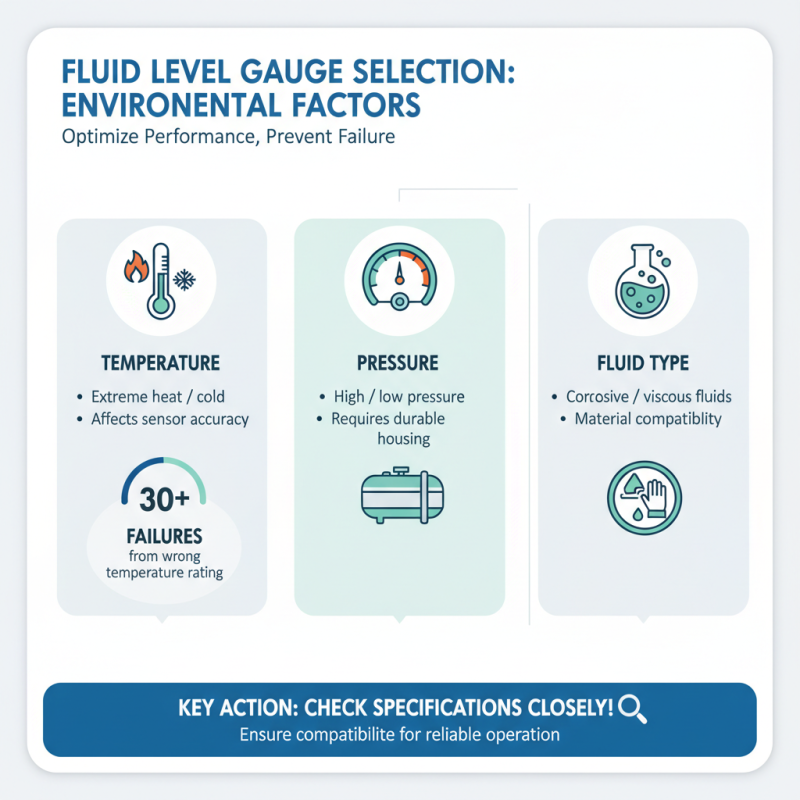

When selecting fluid level gauges, environmental conditions play a crucial role. Temperature, pressure, and the fluid type are key factors. For example, extreme temperatures can affect sensor performance. Studies indicate that over 30% of gauge failures occur due to improper temperature ratings. It’s necessary to check the specifications closely.

Locations also matter. High humidity or corrosive environments may require specific materials. Rough conditions may impact readings. According to industry data, nearly 25% of gauges in harsh environments face degradation. Consider factors like exposure to chemicals as well. These can lead to inaccurate measurements or even complete failures.

Additionally, installation conditions should not be overlooked. Space constraints can limit gauge options. If the installation area has limited accessibility, maintenance will be a challenge. Frequent upkeep may be needed in tough environments. Reflecting on these elements before choosing a gauge can enhance reliability significantly. Offering a balance between performance and durability is vital in fluid level gauge selection.