In the ever-evolving industrial landscape of 2025, selecting the right components for operational efficiency has become crucial. Among these components, lined valves play a pivotal role in ensuring the integrity and performance of various systems, particularly in environments where corrosion and wear pose significant challenges. The demand for reliable lined valves is on the rise, as industries increasingly seek solutions that offer durability, efficiency, and cost-effectiveness.

Choosing the best lined valves for your industrial needs is not merely a matter of preference, but a necessity for maintaining optimal performance and safety standards. With a multitude of options available in the market, understanding the specific requirements of your application is essential. This overview will equip you with critical insights into the features, types, and performance metrics of lined valves, helping you make informed decisions tailored to your operational demands. Whether you are in the chemical, petrochemical, or wastewater management sectors, the right lined valves can enhance productivity and extend the lifecycle of your systems.

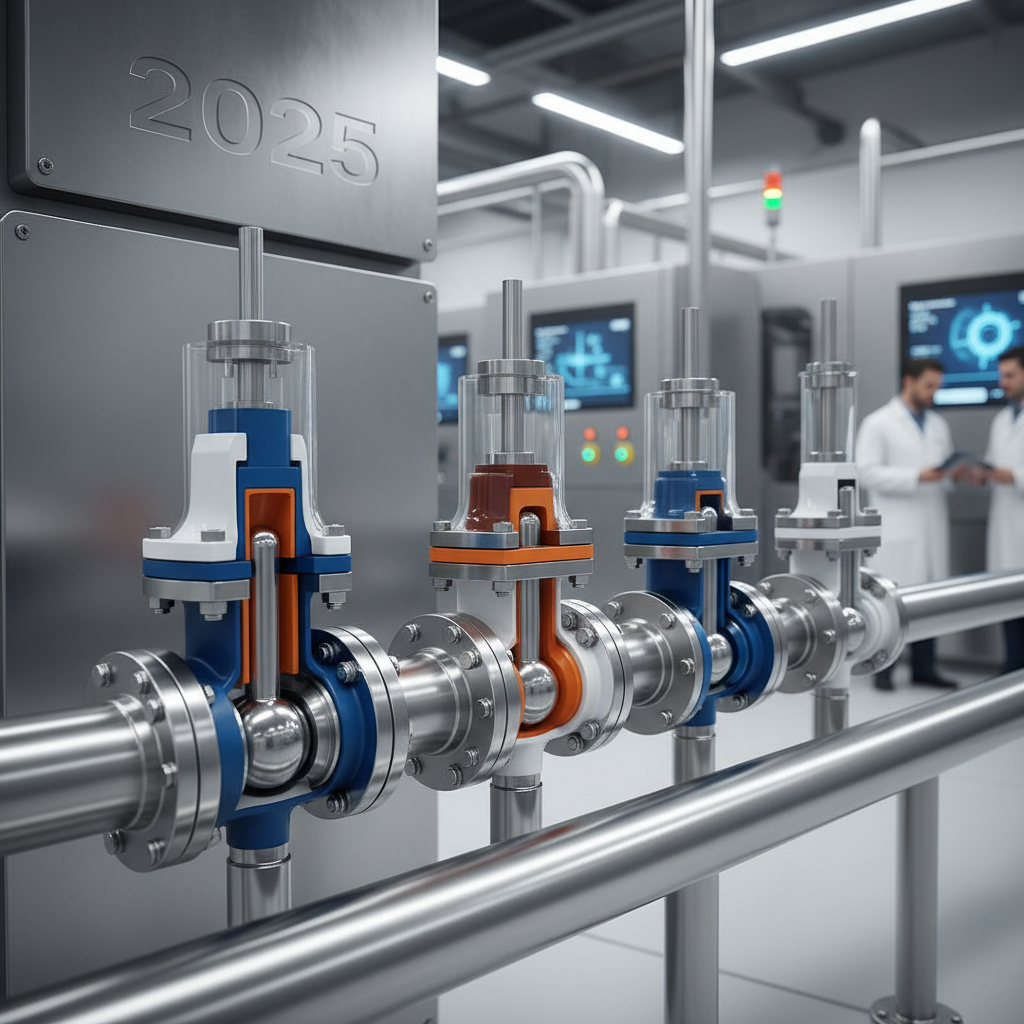

When selecting lined valves for industrial applications, it’s essential to understand the various types available and their specific functionalities. Lined valves are designed to handle aggressive media, providing protection against corrosion and wear. Key types include diaphragm valves, which utilize a flexible membrane to control flow, making them ideal for slurries and corrosive fluids. Another popular option is the lined ball valve, known for its reliability and ability to provide a tight seal, suitable for high-pressure applications.

Additionally, lined butterfly valves are advantageous for applications that require quick shut-off and reduced space. They are particularly effective in handling large volumes of liquid with minimal pressure drop.

When choosing the appropriate lined valve, consider factors such as the media type, pressure and temperature conditions, and any regulatory standards that may apply. Each valve type has distinct advantages, and understanding these will ensure optimal selection for your specific industrial needs.

When selecting lined valves for industrial applications, evaluating their reliability based on key performance metrics is crucial. A report from the World Economic Forum indicates that approximately 30% of maintenance costs in industrial sectors can be attributed to valve failures, underscoring the need for reliable lined valve solutions. Reliability can be assessed through several factors, including leakage rates, operational lifespan, and resistance to corrosive environments. For instance, lined valves with PTFE coatings often demonstrate significantly lower leakage rates compared to traditional options, making them indispensable for high-pressure chemical applications.

In addition to leakage, durability under extreme temperatures is another critical metric. According to research published by the American National Standards Institute (ANSI), valves that can withstand temperatures over 150°C with consistent performance represent a growing segment in process industries, where thermoplastic lined valves are gaining traction. Monitoring the fatigue resistance and overall wear over time will not only ensure operational integrity but will also contribute to a reduced total cost of ownership. Investing in lined valves with superior performance metrics can lead to enhanced productivity and safer operational environments across various industrial applications.

When selecting lined valves for industrial applications, material compatibility is paramount to ensure optimal performance and longevity. The lining material must be able to withstand the specific chemicals and conditions it will encounter in the process. For instance, if your process involves corrosive chemicals, materials such as PTFE or rubber linings may be necessary to provide the required resistance. Understanding the chemical properties of the substances involved, including pH levels and temperature ranges, is crucial in making an informed choice.

Additionally, the physical demands of the environment should not be overlooked. Consider factors such as abrasion, pressure, and temperature fluctuations, as these can significantly impact the integrity of the lining over time. Different linings offer varying degrees of durability and resistance to wear, so evaluating the expected operational conditions will aid in selecting the most suitable linear option. By prioritizing material compatibility with both the chemicals and environmental conditions, industries can achieve reliable valve performance, minimizing maintenance costs and downtime.

When selecting lined valves for industrial applications, understanding the applicable industry standards and regulations is crucial. These guidelines not only ensure compliance but also guarantee the safety and efficiency of operations. Various sectors, such as chemical, pharmaceutical, and food processing, adhere to specific standards set by organizations like the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO). Familiarity with these regulations helps in identifying the right materials, coatings, and configurations for lined valves that can withstand the operational environment, including temperature, pressure, and corrosive substances.

Moreover, regulations concerning environmental impact and safety, such as the Environmental Protection Agency (EPA) guidelines, play a significant role in the selection process. These regulations dictate the types of materials that can be used, especially in industries where leakage prevention is critical. Advanced lining materials, such as polypropylene or PTFE, may be required to meet these regulatory demands. Therefore, buyers should not only consider the technical specifications of lined valves but also how they align with the relevant standards to ensure optimal performance and compliance throughout the lifecycle of the equipment.

This chart illustrates the factors impacting the selection of lined valves in industrial applications according to industry standards and regulations. Data represents the average importance rating (1-10) of each factor based on a survey of industry professionals.

When considering lined valves for industrial applications, a cost-benefit analysis is essential for making informed decisions that ensure long-term efficiency and durability. Investing in high-quality lined valves might seem like a significant upfront cost, but the advantages they bring over cheap alternatives far outweigh the initial expenditure.

Premium lined valves are designed to withstand harsh operating conditions, reducing the frequency of replacements and repairs. This longevity translates into lower maintenance costs and minimized downtime, which are critical factors in maintaining productivity in any industrial environment.

Moreover, the right lined valves can enhance operational safety by preventing leaks and failures that could lead to costly incidents or environmental hazards. By doing a thorough assessment of the potential costs associated with valve failures and evaluating the reliability of various options, companies can better understand the return on investment for quality lined valves. Ultimately, investing in superior products not only leads to better performance and reduced risks but also supports sustainable practices that can be crucial in today’s environmentally-conscious marketplace.