When it comes to industrial processes, understanding and managing the flow of materials is crucial for operational efficiency and safety. A vital tool in achieving this is the flow indicator, which provides real-time data on the movement of liquids and gases within pipelines. Choosing the right flow indicator is imperative for ensuring accurate measurements and optimizing system performance. This decision can impact not only the effectiveness of equipment but also the overall productivity of operations across various industrial sectors.

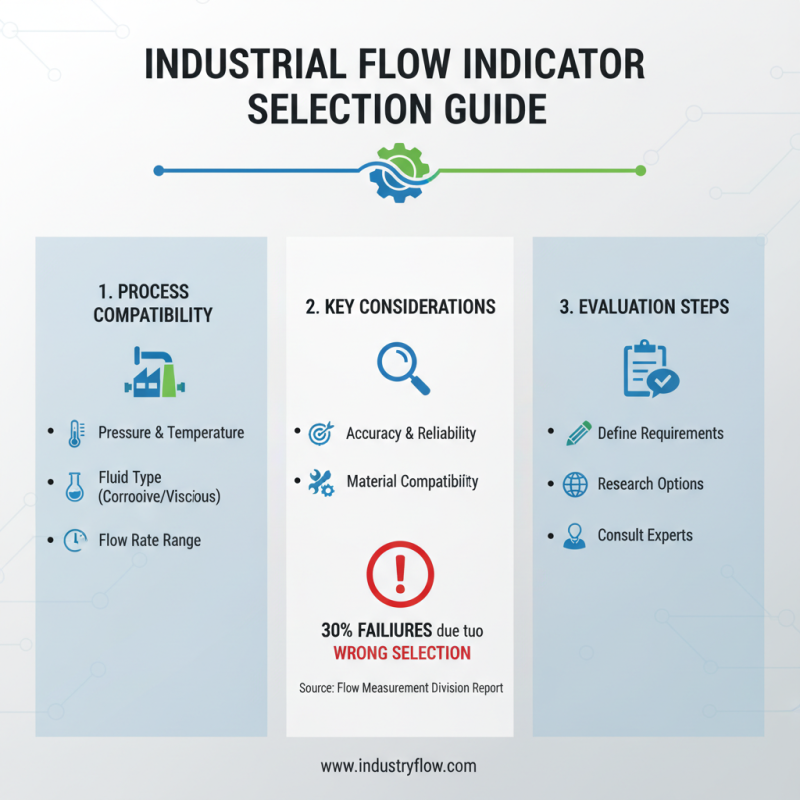

In selecting the most suitable flow indicator, several factors must be considered, including the type of fluid, the flow rate, and the operating conditions such as temperature and pressure. Furthermore, understanding the required accuracy and any potential environmental challenges is essential for making an informed choice. With numerous options available, it’s important to assess the specific needs of your application to ensure you select a flow indicator that aligns with your operational goals. Whether you are monitoring water, chemicals, or gases, the right flow indicator can vastly improve your ability to track flow rates and enhance your industrial processes.

Flow indicators are essential tools in various industrial processes, providing real-time insight into the flow of liquids and gases. Understanding the types of flow indicators available is crucial for selecting the right instrument for your specific needs. Common types include mechanical indicators, such as paddle and turbine flow indicators, which utilize physical components to measure flow rates. Additionally, there are electronic flow indicators that rely on sensors and advanced technology to offer more precise readings, suitable for applications requiring high accuracy.

Applications of flow indicators span a diverse range of industries, from manufacturing to oil and gas. In water treatment facilities, for instance, flow indicators help monitor water levels and ensure efficient processing. Similarly, in the chemical industry, they play a vital role in maintaining the correct flow of corrosive and hazardous materials, enabling safe and efficient operations. When choosing a flow indicator, factors such as the type of fluid, flow rate range, and environmental conditions must be considered to ensure optimal performance and reliability in operation.

When selecting a flow indicator for industrial applications, various key factors play a crucial role in ensuring optimal performance and reliability. The first consideration is the fluid type being measured. Different fluids can have varying properties such as viscosity, temperature, and chemical composition, which affect how they flow. According to a report by the American Society of Mechanical Engineers (ASME), the viscosity of the fluid can significantly impact the accuracy of flow measurement. For instance, high-viscosity fluids may require indicators designed specifically to handle such characteristics, thereby minimizing the risk of inaccuracies.

Another important factor is the operating environment, including pressure and temperature ranges. Flow indicators must be chosen based on their ability to withstand these conditions. The Global Industry Analysts Inc. states that maximum operating pressure and temperature specifications can differentiate between suitable and unsuitable instruments for specific tasks. Furthermore, the installation requirements, including space constraints and orientation, can also dictate the appropriate flow indicator types. Evaluating these conditions in conjunction with application-specific requirements ensures that the selected flow indicator will function efficiently and reliably within its intended industrial context.

Additionally, understanding the monitoring and maintenance needs of flow indicators is essential. Regular maintenance schedules can differ widely depending on the design and application of the indicator. Reports suggest that improper maintenance can lead to a 30% increase in operational costs due to unscheduled downtime. Therefore, selecting flow indicators with ease of maintenance in mind will not only enhance reliability but also contribute to long-term cost efficiency in industrial operations.

When selecting a flow indicator for industrial applications, compatibility with existing processes is paramount. Understanding the specific requirements of your production environment—including pressure, temperature, and the types of fluids being handled—is crucial for effective operation. According to a recent industry report by the Flow Measurement Division, more than 30% of flow measurement failures can be attributed to improper selection of corresponding indicators, emphasizing the importance of thorough evaluation.

When assessing flow indicators, consider their ability to withstand the unique conditions of your operation. For instance, materials used in the construction of the indicator should resist corrosion and abrasion for environments featuring harsh chemicals or particulate-laden fluids. The right choice of flow indicator can improve process reliability, reduce downtime, and ensure optimal plant efficiency. A study from the Institute of Industrial Process Engineering indicates that well-calibrated flow indicators can enhance measurement accuracy by up to 15%, leading to significant cost savings over time.

**Tips:** Always consult technical datasheets and ensure that the parameters listed align with your operational requirements. Conducting a compatibility test with small batches before full-scale implementation can mitigate risks of operational disruptions and help identify any necessary adjustments.

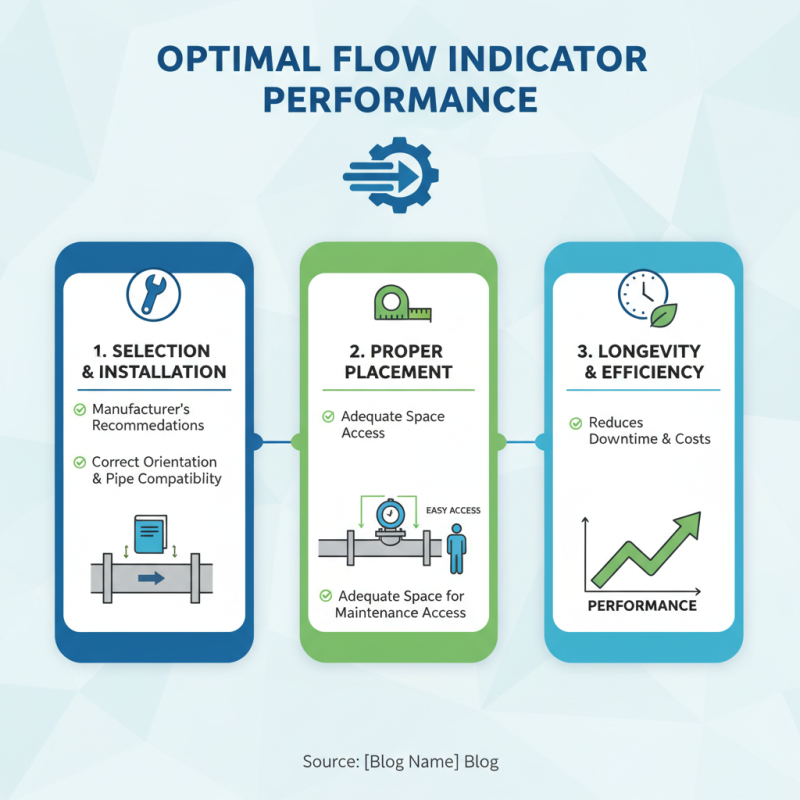

When selecting a flow indicator for industrial applications, proper installation and maintenance are crucial for optimal performance and longevity. First, it's essential to ensure that the flow indicator is installed in accordance with the manufacturer’s recommendations. This includes positioning the device in the correct orientation to avoid turbulence and ensuring that the pipe diameter is compatible. Adequate space around the flow indicator allows for easy access during maintenance, so planning the installation site carefully can save time and resources later.

Regular maintenance of flow indicators is equally important to prevent failures and ensure accurate readings. This may involve periodic cleaning to remove any build-up of contaminants, which can obstruct flow and lead to inaccurate measurements. It’s also advisable to check the seals and fittings for any signs of wear or leaks that may compromise the functionality of the indicator. Establishing a routine maintenance schedule will help in identifying potential issues early, ultimately reducing downtime and ensuring the flow indicator continues to operate efficiently within the industrial system.

When selecting a flow indicator for industrial applications, cost-effectiveness and performance efficiency are crucial factors to consider. Cost-effectiveness involves not only the initial purchase price but also the long-term operational costs associated with maintenance, calibration, and potential downtimes. Investing in a flow indicator that offers reliable performance can significantly reduce these hidden costs, making it a smarter choice for businesses aiming to optimize their budgets.

Performance efficiency is equally vital, as it directly impacts the accuracy and responsiveness of the flow measurement. A high-performance flow indicator should provide real-time data and maintain precision under varying operational conditions. An efficient flow indicator will help prevent over- or under-utilization of resources, thereby enhancing overall productivity. By prioritizing both cost-effectiveness and performance efficiency, industries can select a flow indicator that not only meets their immediate needs but also supports their long-term operational goals.