In the realm of fluid control, the use of advanced materials and technologies has become increasingly vital for ensuring efficiency and reliability. One of the standout components in this field is the Teflon check valve, revered for its exceptional performance and durability. Designed to facilitate one-way flow of liquids and gases, Teflon check valves offer an array of benefits that are pivotal to various industrial applications. Their unique properties make them particularly suitable for handling corrosive substances, high temperatures, and challenging operating environments.

The chemical resistance and low friction characteristics of Teflon, or PTFE, enable these check valves to maintain operational integrity while minimizing wear and tear. This not only extends their lifespan but also enhances the overall performance of fluid systems. Additionally, Teflon check valves are known for their ease of installation and maintenance, making them a preferred choice for engineers and operators looking to optimize their fluid control processes. As industries continue to evolve, the demand for reliable and efficient fluid control solutions will only grow, placing Teflon check valves at the forefront of innovative fluid management technologies.

Teflon check valves have gained increasing attention in the field of fluid control due to their outstanding chemical resistance and durability. Made from polytetrafluoroethylene (PTFE), Teflon check valves are designed to prevent backflow in piping systems, ensuring that fluids flow in a single direction. According to a market analysis by Research and Markets, the global market for check valves is expected to reach over $30 billion by 2025, reflecting the growing demand for efficient fluid management solutions across various industries, including chemical processing and pharmaceuticals.

The unique properties of Teflon, such as its non-stick nature and exceptional thermal stability, make Teflon check valves ideal for handling aggressive and corrosive fluids. A study published in the Journal of Fluid Engineering highlights that Teflon check valves exhibit remarkable performance in high-pressure and high-temperature environments, which are common in industrial applications. This capacity minimizes maintenance costs and downtime by preventing leaks and failures, reinforcing the reliability that operators seek in fluid control systems.

Moreover, Teflon check valves are lightweight and easy to install, contributing to their efficiency in fluid dynamics applications. The flexibility of Teflon allows these valves to accommodate a wider range of temperatures, from cryogenic conditions to soaring heat levels, while maintaining their integrity over time. This versatility enhances their appeal, making them a preferred choice for engineers and system designers aiming for optimal performance in fluid handling processes.

Teflon check valves are increasingly recognized in fluid control applications due to the unique advantages offered by Teflon material itself. One of the primary benefits is Teflon’s exceptional resistance to corrosion and chemical degradation, making it ideal for handling aggressive fluids across a wide range of industries. According to a report by the Chemical Engineering Progress, Teflon’s resilience allows it to maintain functionality in environments where traditional materials might falter, including exposure to strong acids and alkalis. This characteristic significantly reduces maintenance costs and equipment downtime, enhancing operational efficiency.

Additionally, Teflon’s low friction properties facilitate smooth flow control, which is particularly advantageous in systems requiring precise fluid modulation. Research published in the Journal of Fluids Engineering suggests that Teflon check valves exhibit lower pressure drops compared to other materials, enhancing system performance and energy efficiency. Furthermore, Teflon prevents the build-up of deposits and scaling due to its non-stick surface; this contributes to prolonged service life and reliability of fluid control systems. As industries increasingly seek sustainable and efficient solutions, the adoption of Teflon check valves continues to rise, aligning with trends towards minimizing environmental impact while optimizing processes.

Teflon check valves offer significant performance advantages in diverse fluid control applications due to their unique properties. One of the primary benefits is their exceptional chemical resistance. Teflon's ability to withstand aggressive substances makes these valves ideal for industries such as pharmaceuticals, chemicals, and food processing, where the integrity of the fluid is crucial. Additionally, Teflon check valves can operate effectively in extreme temperatures, providing reliable performance in both high and low-temperature environments.

Another key advantage of using Teflon check valves is their low friction characteristics, which contribute to improved flow efficiency. The smooth surface of Teflon minimizes turbulence and wear, resulting in a longer lifespan for the valve and reduced maintenance costs. This feature is particularly beneficial in systems requiring high flow rates or where fluid viscosity varies. Furthermore, the lightweight nature of Teflon facilitates easier installation and handling, enhancing overall operational efficiency across various applications, from industrial processing to water management systems.

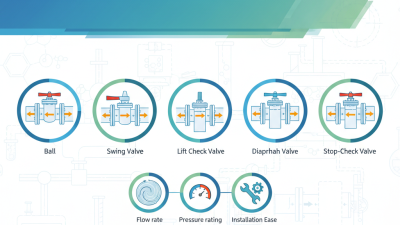

This chart illustrates the performance benefits of Teflon check valves across various applications, highlighting attributes such as chemical resistance, temperature tolerance, and pressure performance.

When comparing Teflon check valves with traditional valve materials, several factors come into play that highlight Teflon's advantageous properties. Traditional materials like brass, stainless steel, or PVC often face limitations in corrosive environments or high-temperature applications. Teflon check valves, made from polytetrafluoroethylene (PTFE), provide exceptional chemical resistance and maintain their functionality over a wider temperature range, making them ideal for demanding industrial applications.

One of the standout features of Teflon is its low-friction characteristics, which allows for smoother operation and minimal pressure drop across the valve. This is especially beneficial in fluid control systems, where maintaining flow efficiency is crucial. Traditional materials may suffer from issues like scale buildup or surface deterioration, which can compromise performance over time. In contrast, Teflon check valves resist fouling and remain clean for longer durations, thus enhancing the longevity of the fluid control system.

Tips for selecting the right check valve include assessing your specific application requirements, such as the type of fluid being handled and the operating temperature. A Teflon check valve is an excellent choice if your application involves aggressive chemicals or extreme temperatures. Additionally, consider the installation environment; Teflon's resilience against wear and tear makes it a smart investment for various industrial contexts. By understanding the strengths of Teflon check valves versus traditional materials, you can make informed choices to optimize your fluid control systems.

| Feature | Teflon Check Valves | Traditional Valve Materials |

|---|---|---|

| Corrosion Resistance | Excellent | Variable (limited resistance) |

| Temperature Range | -200°C to 260°C | Up to 200°C (depends on material) |

| Weight | Lightweight | Heavier (e.g., metal) |

| Maintenance | Low | Higher |

| Flow Efficiency | High | Moderate |

| Cost | Higher initial cost | Lower initial cost |

| Applications | Chemical processing, pharmaceuticals | Water, oil, gas |

Teflon check valves are renowned for their exceptional resistance to a wide range of chemicals and their ability to operate effectively in various temperatures. However, their maintenance and longevity significantly enhance their performance and operational lifespan. Regular inspections are crucial; ensuring that the valve is free from debris and any buildup that can impede its functionality helps maintain fluid flow efficiency. Additionally, routine checks for wear and tear can prevent unexpected failures, guaranteeing that the valve continues to operate effectively in demanding environments.

Proper lubrication is another vital aspect that contributes to the longevity of Teflon check valves. Unlike traditional valves, Teflon’s low friction properties minimize wear, but periodic application of compatible lubricants can help in reducing potential friction points even further, ensuring smooth operation. Moreover, choosing the right installation position and orientation is essential. An ideal setup minimizes stress on the valve components, thereby prolonging their life. By adhering to these maintenance practices, users can maximize the benefits derived from Teflon check valves, ensuring consistent performance and reliability over time.