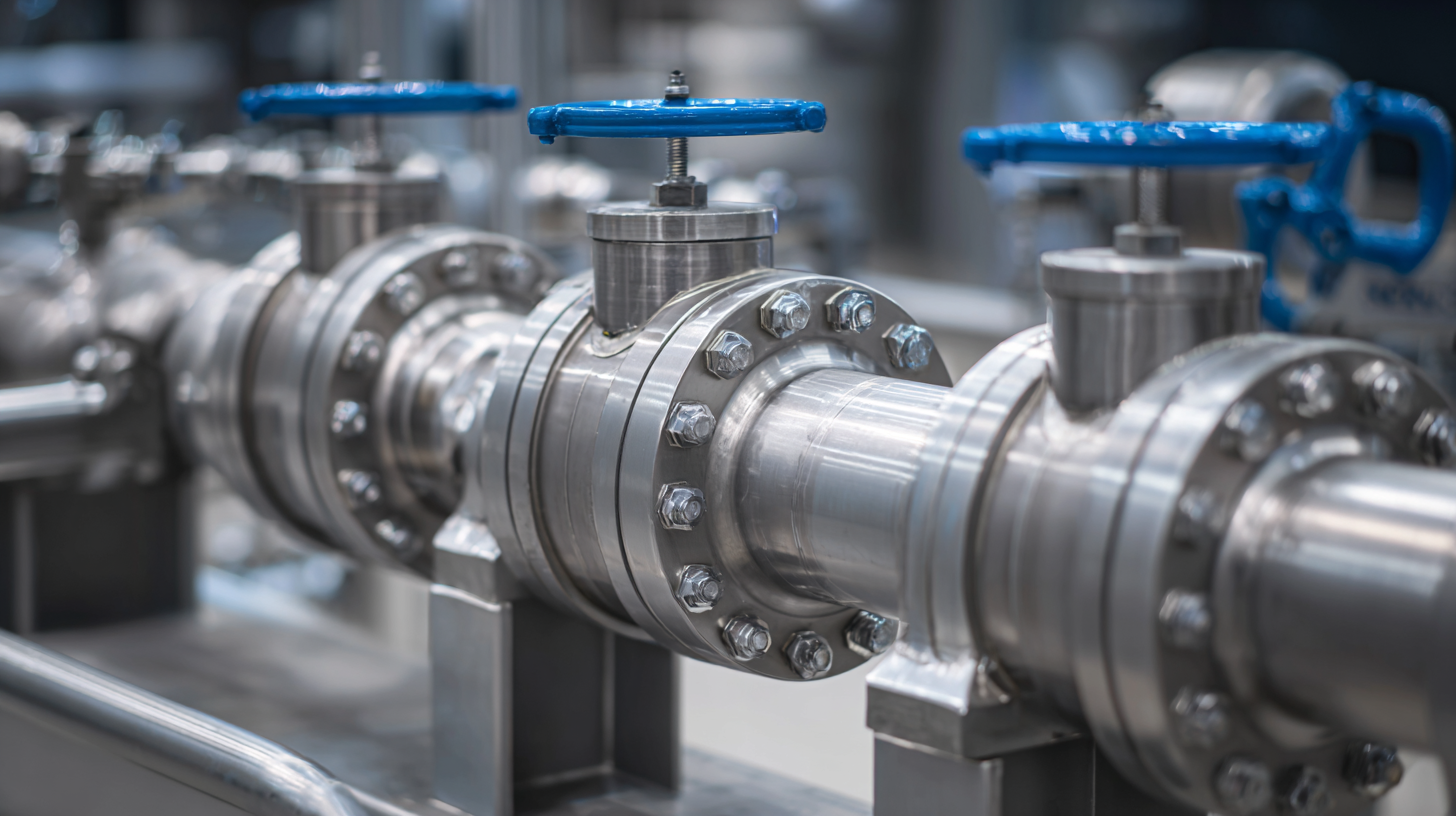

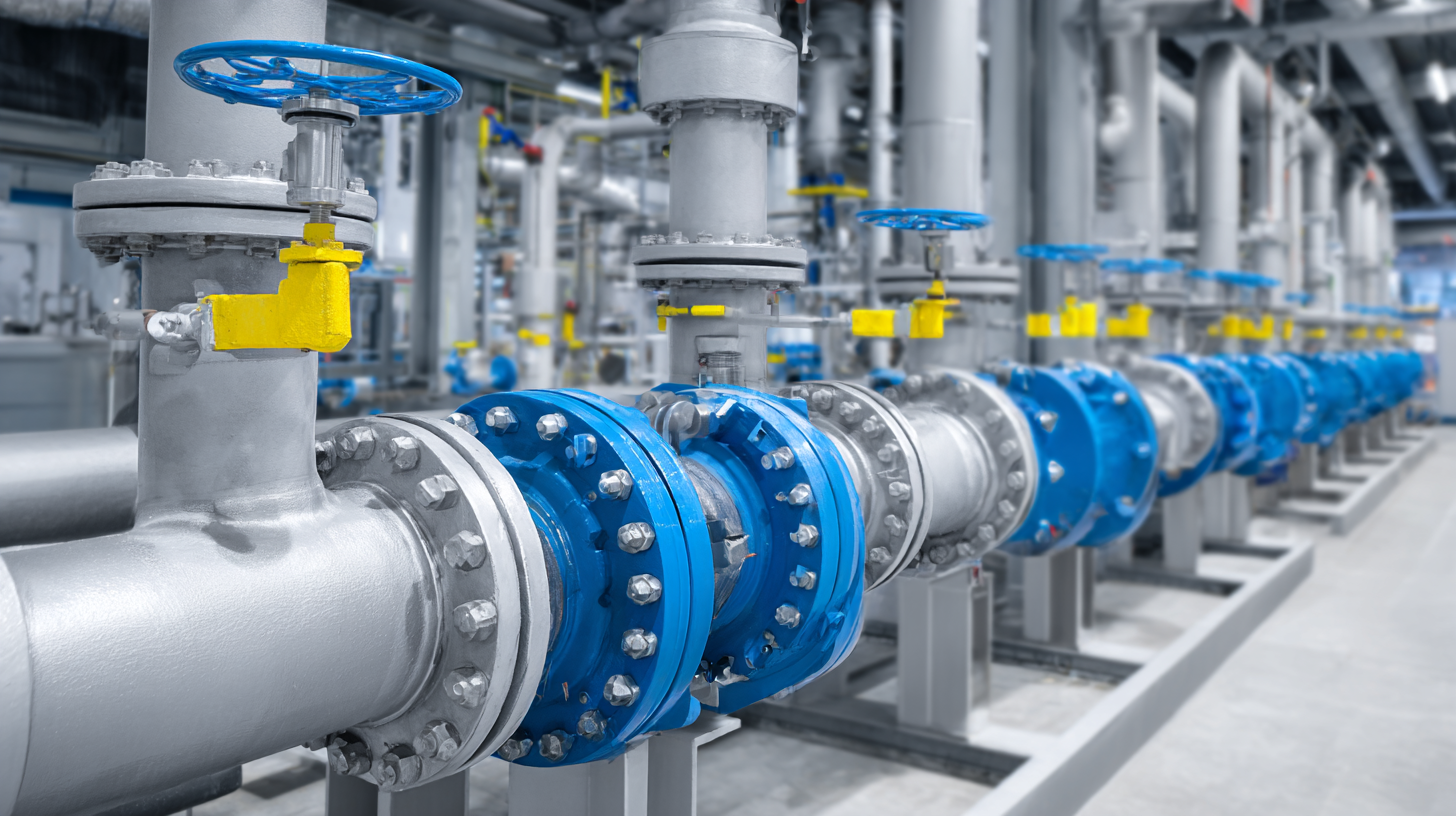

In the realm of chemical processing, the selection of appropriate equipment is paramount to ensure safety, efficiency, and longevity.  PTFE lined valves have emerged as a pivotal component in this sector, offering exceptional resistance to chemical corrosion and elevated temperatures. According to a recent report by the Global Market Insights, the demand for PTFE lined valves is projected to witness a significant increase, driven by stringent regulations governing the chemical industry and the need for reliable valve performance in harsh environments.

PTFE lined valves have emerged as a pivotal component in this sector, offering exceptional resistance to chemical corrosion and elevated temperatures. According to a recent report by the Global Market Insights, the demand for PTFE lined valves is projected to witness a significant increase, driven by stringent regulations governing the chemical industry and the need for reliable valve performance in harsh environments.

These valves not only enhance operational reliability but also reduce maintenance costs, as their PTFE lining minimizes wear and tear caused by aggressive chemicals. Consequently, understanding the advantages of PTFE lined valves is crucial for professionals aiming to optimize their processing systems while adhering to safety and sustainability standards.

In the realm of chemical processing, managing corrosive substances effectively is paramount, and PTFE lined valves have emerged as an invaluable solution. PTFE, or polytetrafluoroethylene, boasts exceptional resistance to a wide range of chemicals, making it ideal for applications involving harsh acids, alkalis, and solvents. According to a report by the Chemical Engineering Association, over 60% of industries utilizing corrosive chemicals have shifted towards using PTFE lined components, resulting in enhanced safety and reduced maintenance costs.

In the realm of chemical processing, managing corrosive substances effectively is paramount, and PTFE lined valves have emerged as an invaluable solution. PTFE, or polytetrafluoroethylene, boasts exceptional resistance to a wide range of chemicals, making it ideal for applications involving harsh acids, alkalis, and solvents. According to a report by the Chemical Engineering Association, over 60% of industries utilizing corrosive chemicals have shifted towards using PTFE lined components, resulting in enhanced safety and reduced maintenance costs.

One of the significant advantages of PTFE lined valves is their ability to minimize the risk of leaks, a crucial aspect in environments handling corrosive materials. With their smooth, non-porous surface, PTFE linings prevent chemical build-up and reduce friction, which can lead to wear over time. This contributes to maintaining operational efficiency and prolonging the lifespan of the valves, further emphasizing their economic benefits.

Tips: Regular inspection and maintenance of PTFE lined valves can help detect wear early, greatly reducing the risk of unexpected failures. When selecting PTFE valves, ensure that they are compatible with the specific chemicals in use to maximize their lifespan and performance. Always consult with suppliers for the best options tailored to your application's needs.

PTFE lined valves have become essential components in chemical processing, particularly in harsh environments where durability and longevity are crucial. The unique properties of PTFE (Polytetrafluoroethylene) provide resistance against a wide range of corrosive substances, high temperatures, and pressures. According to a report by the Chemical Engineering Journal, PTFE offers exceptional resistance to over 90% of known chemicals, making it an ideal choice for industries handling aggressive materials, such as acids and alkalis.

In terms of mechanical integrity, PTFE lined valves significantly reduce wear and tear, contributing to lower maintenance costs over time. Studies indicate that equipment failures in chemical processing can lead to unplanned downtime and repairs, averaging costs of around $200,000 per minute of lost production. Implementing PTFE lined valves can mitigate these risks, with manufacturers reporting a lifespan increase of 20-30% compared to traditional valve materials. This enhancement in durability not only improves operational efficiency but also ensures a safer working environment amidst potentially hazardous conditions.

The cost-effectiveness of PTFE lined valves in chemical processing systems is largely attributed to their durability and resistance to corrosion and chemical wear. PTFE, or polytetrafluoroethylene, provides a non-reactive surface that significantly extends the lifespan of valves, reducing the frequency of replacements. This longevity translates into lower maintenance costs and prevents costly downtime associated with valve failures. As chemical processing environments can be particularly harsh, the investment in PTFE lined valves proves to be economically advantageous over time.

Moreover, the initial capital investment in PTFE lined valves often yields long-term savings. Traditional valves may require frequent repairs or replacements, leading to recurring expenditures that can escalate quickly. In contrast, PTFE lined valves, by virtue of their robust design and material properties, tend to minimize these recurring costs. Additionally, as they maintain consistent performance under varying pressures and temperatures, they enhance system efficiency, further contributing to overall cost savings in chemical processing.

Through appropriate selection of PTFE lined valves, companies can achieve operational efficiency while managing their budget more effectively. This results not only in a direct financial benefit but also in optimized workflow and reduced operational risks, making PTFE lined valves a smart choice for chemical processing applications.

PTFE lined valves are becoming increasingly popular in chemical processing applications due to their superior safety features and significant reduction in leakage risks. The unique properties of polytetrafluoroethylene (PTFE) provide excellent chemical resistance, allowing these valves to withstand harsh environments without degrading. This characteristic is essential for maintaining the integrity of the entire system, as even minor leaks can lead to hazardous situations or costly downtime.

When considering PTFE lined valves, it’s crucial to ensure that they are properly installed and maintained to maximize their benefits. **Tip:** Regular inspections can help identify any wear or damage early, preventing potential safety issues. Additionally, it’s advisable to choose the right valve type based on the specific chemicals being processed, as compatibility can greatly enhance performance.

Incorporating PTFE lined valves into your chemical processing operations can significantly improve safety and performance. **Tip:** Always consult with a valve specialist when selecting PTFE lined options to ensure optimal configuration for your system's needs. This proactive approach not only mitigates leakage risks but also contributes to a safer work environment overall.

PTFE lined valves are increasingly recognized for their versatility and adaptability in a wide array of chemical processing applications. The unique properties of Polytetrafluoroethylene (PTFE) provide exceptional chemical resistance, making these valves suitable for handling aggressive and corrosive substances. This feature allows industries such as pharmaceuticals, petrochemicals, and food processing to utilize PTFE lined valves effectively across diverse environments, ensuring the integrity of both the materials transported and the equipment used.

Additionally, PTFE lined valves can be customized to meet specific operational requirements. Their adaptability extends to different configurations, such as ball, butterfly, and gate valves, allowing for seamless integration into existing systems. Furthermore, these valves can function effectively under extreme temperatures and varying pressures, enhancing their usability in challenging conditions. The combination of durability and flexibility makes PTFE lined valves a valuable asset in optimizing processes, reducing downtime, and minimizing maintenance costs across various applications.

| Application | Benefits of PTFE Lined Valves | Common Industries | Temperature Resistance (°C) | Chemical Compatibility |

|---|---|---|---|---|

| Pharmaceutical Manufacturing | Corrosion resistance, Easy cleaning | Pharmaceuticals, Biotechnology | -29 to 260 | Highly acidic and alkaline solutions |

| Food and Beverage | FDA compliance, Sterilization capable | Food Processing, Beverage Industry | -20 to 200 | Food-grade chemicals |

| Petrochemical | Durability, Leakage prevention | Oil and Gas, Petrochemicals | -50 to 200 | Hydrocarbons, Solvents |

| Chemical Production | High-pressure handling, Versatility | Chemical Manufacturing | -40 to 260 | Strong acids and bases |

| Water Treatment | Reliable sealing, Reduces leakage | Wastewater Treatment, Desalination | -10 to 180 | Chlorine, Fluoride |