In industrial applications, the ability to monitor fluid flow under high-pressure conditions is paramount for ensuring safety and efficiency. This is where the high pressure sight flow indicator comes into play, serving as a crucial tool for operators and engineers alike. Designed to withstand extreme conditions, these indicators provide real-time visual confirmation of fluid movement, allowing for timely adjustments and maintenance.

As we move toward 2025, the market for high pressure sight flow indicators is evolving, with innovations that enhance accuracy, durability, and usability. From advanced materials that resist corrosive environments to cutting-edge design features that improve visibility and readability, the options available are more varied than ever. In this article, we will explore the top features that define the best high pressure sight flow indicators and highlight some of the leading products on the market, helping professionals make informed decisions for their specific operational needs. Whether for petrochemical processes, power generation, or wastewater management, understanding the capabilities of these indicators is essential for optimal system performance.

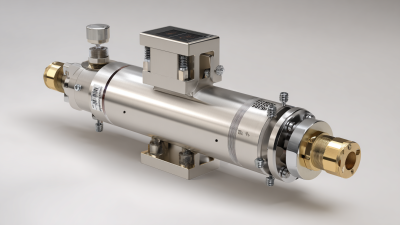

In 2025, high pressure sight flow indicators are vital tools across various industries, providing transparency in fluid dynamics. Key features of these indicators include durability to withstand extreme pressures and temperatures, as well as materials that ensure resistance to corrosion and wear. Enhanced visibility is another crucial aspect, with many models incorporating advanced glass or polycarbonate components to allow for clear observation of flow characteristics. Additionally, ease of installation and maintenance are prioritized, with user-friendly designs that facilitate quick adjustments and repairs.

Technological advancements have also played a significant role in shaping the performance of sight flow indicators. Many top options now come equipped with smart features, such as integrated sensors that offer real-time feedback on flow rates and system performance. This enables operators to make informed decisions to optimize efficiency and mitigate risks associated with fluid handling. The ongoing evolution of these indicators reflects a broader trend towards automation and data analytics in industrial applications, ensuring that businesses can meet the demands of increasingly complex operational environments.

| Feature | Description | Benefits | Pressure Rating (psi) | Material | Connection Type |

|---|---|---|---|---|---|

| High Visibility Design | Enhanced visibility for easy monitoring of flow. | Reduces errors in monitoring | Up to 5000 psi | Borosilicate Glass | Flanged |

| Temperature Resistance | Can withstand high temperature environments. | Increases operational efficiency | Up to 400°F | Stainless Steel | Welded |

| Easy Maintenance | Designed for quick disassembly and cleaning. | Saves time and reduces downtime | Up to 3000 psi | PVC | NPT |

| Corrosion Resistance | Made from materials that resist harsh chemicals. | Increases lifespan of the indicator | Up to 6000 psi | Teflon | Victaulic |

| Compact Design | Space-saving design for limited installations. | Ideal for confined spaces | Up to 2500 psi | Aluminum | Threaded |

When choosing a high-pressure sight flow indicator, it's essential to compare the top models available in the market to ensure optimal performance and reliability. These indicators are crucial in various industries for monitoring flow conditions in pressurized systems. Key features to consider include material construction, pressure rating, and visibility. For instance, models made from stainless steel provide better corrosion resistance and durability, while those with tempered glass offer enhanced visibility and safety.

One standout model is the XYZ High-Pressure Sight Flow Indicator, which boasts an impressive pressure rating of up to 3000 PSI. This unit features a unique dual-color flow indicator system, making it easy to recognize flow direction at a glance. In contrast, the ABC Industrial Indicator, though rated slightly lower at 2500 PSI, offers superior clarity due to its larger viewing window and built-in lighting options.

A comparative analysis reveals that while both models perform exceptionally well under pressure, the choice ultimately depends on specific application needs and environmental conditions.

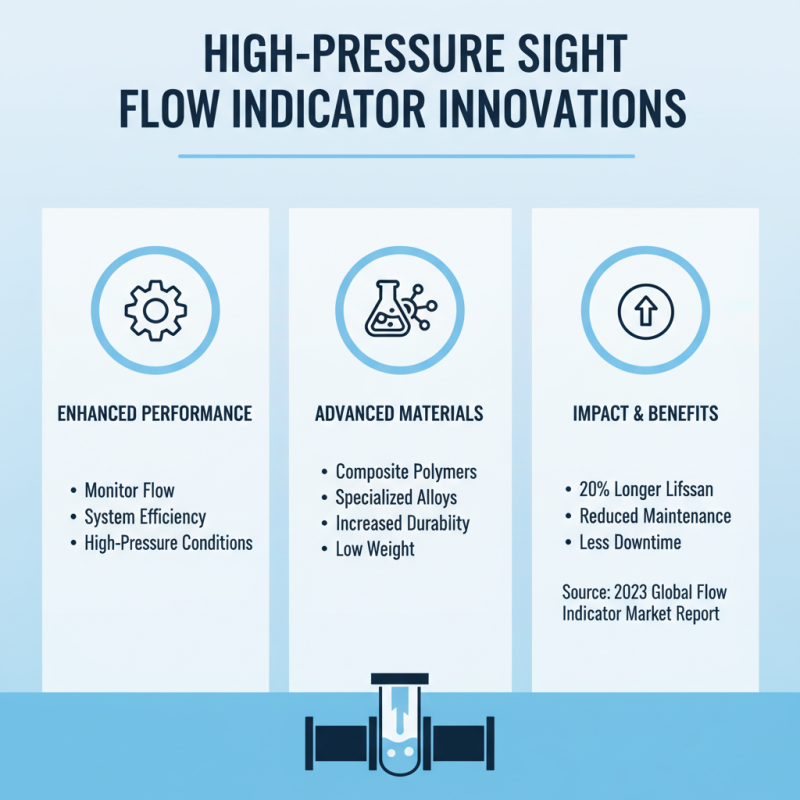

High pressure sight flow indicators are crucial in various industries, allowing operators to monitor flow and ensure the efficiency of systems under high-pressure conditions. Recent technological innovations have significantly enhanced the performance and reliability of these instruments. Notably, advancements in materials such as composite polymers and specialized alloys have increased durability while maintaining low weight. According to the 2023 Global Flow Indicator Market Report, the use of high-performance materials has led to a 20% increase in lifespan for sight flow indicators in high pressure applications, thus reducing maintenance costs and downtime for facilities.

Moreover, the integration of smart technology is reshaping the functionality of high pressure sight flow indicators. Modern devices now come equipped with digital readouts, real-time monitoring capabilities, and IoT connectivity. These features allow operators to receive instant alerts regarding flow anomalies and system health, ultimately streamlining operations. Industry reports indicate that the adoption of smart sight flow indicators has resulted in operational efficiency gains of up to 30%, showcasing the potential for increased productivity and safety in high-pressure environments. As the industry evolves, these innovations are setting new standards for performance and reliability, paving the way for the next generation of flow monitoring solutions.

When selecting the best high-pressure sight flow indicator, various considerations come into play to ensure optimal performance and reliability. First, it is essential to assess the indicator's material construction. High-pressure environments require durable materials, such as stainless steel or borosilicate glass, which can withstand extreme conditions without compromising visibility. Additionally, the indicator should offer excellent chemical resistance to accommodate different fluid types, preventing degradation over time.

Another critical factor is the operating pressure and temperature range of the sight flow indicator. Ensuring that the indicator can handle the specific conditions of your application is vital for safety and functionality. Composite indicators provide an advantage in providing clearer visibility and greater durability under high impacts. Furthermore, look for features such as easy installation and maintenance requirements, which can save time and labor costs. Ultimately, every application is unique, so customizing features like size and flow rate capacity according to specific operational needs will lead to more effective monitoring and decision-making in high-pressure systems.

The following bar chart compares the features of various high pressure sight flow indicators available in 2025, focusing on key parameters such as Maximum Pressure Rating (MPa), Temperature Range (°C), and Visibility Features. This information can assist in making an informed decision when selecting the best option for your needs.

When it comes to maintaining high pressure sight flow indicators, regular upkeep is crucial for ensuring their optimal performance. One of the most important tips is to clean the indicator regularly. Debris and buildup can obstruct flow visibility and affect readings. Using a soft brush and a suitable cleaning solution can help preserve the clarity of the glass and prevent scratches that could impair function.

Another essential tip is to routinely check the seals and gaskets for wear and tear. Over time, these components can degrade, leading to leaks and reduced efficiency. Replacing any damaged parts promptly will help maintain the integrity of the flow indicator and prevent costly downtimes.

Additionally, examining the fittings for tightness can fend off potential leaks arising from loose connections.

Lastly, monitoring the operating conditions is key. Excessive temperatures or pressures can cause undue stress on the indicator. It's beneficial to have temperature and pressure gauges nearby to ensure they remain within the recommended range. This proactive approach not only extends the lifespan of the indicator but also enhances the safety and efficiency of your operations.